TBM Co., Ltd. was founded in August 2011 and is a venture company that has been in business for only 10 years. It develops, manufactures and sells "LIMEX" (registered trademark), which is a plastic alternative and a paper alternative and contains 50% or more of inorganic substances such as calcium carbonate.

There are materials all over the world that are used to reduce the amount of plastic and paper usage but with a high energy load that causes environmental destruction. TBM also aims to achieving the early expansion of such alternative materials. LIMEX was developed as a material that meets the extremely strict conditions that it must be a general-purpose material and that the manufacturing method must be able to use existing equipment. Currently, TBM specializes in the development, manufacture and sale of LIMEX.

LIMEX is used by more than 8,000 companies and public institutions that are highly conscious of reducing environmental impact.

LIMEX product range

Risk of resources depletion can be reduced by using LIMEX

Since plastic products are made from naphtha, a product made from fossil fuel, CO2 is emitted when they are incinerated, which is considered to be a factor in climate change. On the other hand, compared to petroleum-derived plastics, LIMEX uses inorganic substances containing calcium carbonate as its main raw material, so it can significantly suppress CO2 throughout the product life cycle.

Huge amount of water is consumed in the paper manufacturing process. By utilizing LIMEX, it will be possible to reduce the amount of water resources used by about 97% (*).

* Value obtained by dividing the amount of water used in the production equipment at the time of the trial production in 2021 at the TBM Tagajo plant by the production amount during that period vs. Changes in the new water utilization intensity per ton of paper and paperboard production quoted from statistics of the Japan Paper Association

Tagajo Plant, Miyagi Prefecture, Northeast Japan

How is LIMEX made?

Utilization of limestone to reduce environmental load

LIMEX is made by combining limestone (calcium carbonate) and a thermoplastic resin such as polypropylene.

The use of limestone has the following advantages.

1. Suppress CO2 throughout the product life cycle

Compared to petroleum-derived plastics, limestone can reduce CO2 emissions at the raw material procurement stage to about 1/50, and can reduce CO2 emissions during combustion by about 58%.

2. Sufficient amount exists all over the world

Unlike fossil fuels, many countries can utilize their own resources.

3. Can be recycled

Since it can be reused, it can contribute to resource conservation.

* In August 2021, TBM announced that it had started a project for one of the largest material recycling plants in Yokosuka City, Kanagawa Prefecture, Japan. A recycling plant that can automatically sort used LIMEX products and waste plastic products is scheduled to be completed around the fall of 2022, and since it can separate LIMEX from miscellaneous plastics, it is expected to improve the domestic material recycling rate of plastic that is currently only at 4.5%.

Recycling plant in Yokosuka City, Kanagawa Prefecture

TBM - A Sustainable Company with Green Credentials

Mr. Yamasaki, Founder and CEO, founded TBM with the idea of "doing a business that is easy to understand and meaningful to the world," "becoming a company that contributes globally," and "doing a business that makes trillions."

Mr. Nobuyoshi Yamasaki, Founder and CEO

1. Commitment to general-purpose materials

TBM has made strong commitments to developing materials that can be used for general purposes. Even if an epoch-making new material is made, the construction cost of the manufacturing equipment is high, it takes time to spread it worldwide, and it takes too much time to reduce the continuous environmental load.

Also, if the production area is limited, as in the case of fossil fuel, for example, the difference between what you have and what you do not have will increase. In that respect, limestone exists all over the world, and the presence or absence of resources does not hinder manufacturing.

2. Climate Pledge 2030 - An Ambitious Goal for TBM

TBM is enthusiastically working on the "TBM Pledge 2030" which aims to achieve carbon negatives by 2030 and circulate 1 million tons of LIMEX and plastics in 50 countries by 2030. The specific contents are as follows.

Go Carbon Negative

1. Zero GHG (Greenhouse Gas) emissions * from TBM

- Energy saving

- Active introduction of renewable energy (considering additionality)

2. Halve GHG emissions* on the value chain compared to FY2020

- Support for the introduction of renewable energy for business partners and customers

- Procurement of products and services with a small carbon footprint

- Decarbonization of the use and disposal method of TBM products

3. Contribute to reducing GHG emissions in society as a whole

- Minimize GHG emissions in the life cycle of products and services

- Technology development and project promotion related to GHG removal

Go Circular

1. Value Innovation

- Transformation into values that regard garbage as a resource

- Improving the added value of products using recycled materials

2. Structural Innovation

- Creating a value chain that balances the maximization of the lifetime value of resources and economic rationality

- Promotion of an inclusive and clean resource recycling industry

3. Technological Innovation

- Development and dissemination of innovative sorting and regeneration technologies

- Development and dissemination of technology that connects stakeholders

* Scope 1: GHG emissions directly from companies (GHG emissions from boilers in their own factories)

Scope 2: Energy-derived indirect emissions (GHG emissions from other companies such as electric power and consumed by the company)

* Scope 3: Raw material procurement, distribution, customer use and GHG emissions at the disposal / recycling stage in the life cycle, etc.

3. Active in business development in emerging countries

- Vietnam

Establishing a local subsidiary "TBM VN Co., Ltd " in Hanoi, Vietnam, the company aims to strengthen price competitiveness and production system in collaboration with local manufacturing partners, and expand sales channels to molding manufacturers in Vietnam. (November 2021)

- Indonesia

TBM concluded an injection molding grade sales contract with PT. Kemas Indah Maju which is the largest cosmetic container molding manufacturer in Indonesia and handles products of major cosmetic manufacturers in Japan and the world, and LIMEX Pellet (material processed into grains of LIMEX) for cosmetic containers. (December 2021)

A sales contract of LIMEX Pellet for injection-molded products has been concluded in order to meet the accelerating needs for reducing environmental impact in the cosmetics industry, cosmetic containers (compact, cosmetic jars, lips, etc.), taking into consideration the quality of major domestic and global cosmetic brands handled by PT. Kemas , etc.

TBM's high technology level that realized the development of LIMEX

1. LIMEX supported by many unique technologies

It is extremely difficult to manufacture resins and films mainly composed of inorganic substances such as limestone. For this reason, TBM repeated research and development and made many unique inventions. Many of them have been granted patents at home and abroad.

LIMEX basic patents ( WO2012165311A (2012.12.6) , etc. ) have been registered in more than 40 countries around the world. As an excellent technology in Japan, it is registered in the Sustainable Technology Dissemination Platform (STePP) of UNIDO (United Nations Industrial Development Organization), and is also subject to the JSA standard "Inorganic / Organic Composite Material" which is a standard in Japan (JSA-S1008).

2. TBM patent evaluation

The TBM patent can be evaluated as follows.

1. The number of patent applications is steadily increasing

The number of TBM patent applications, including foreign applications, is steadily increasing, and 16 (family-based) in 2019 are many for start-up companies. In addition, many have been filed for PCT internationally, and applications have been made with an eye on overseas business development.

It is also active in applying for patents overseas, and is applying to all possible markets in the future. Overseas, TBM has a strategy of aiming to expand its business by licensing it to partners, and is solidifying the foundation for future business alliances.

2. TBM has obtained a patent without omission centered on the basic patent

TBM has a strategy of obtaining all peripheral patents centered on basic patents, including products such as composite materials that are raw materials on the upstream side, resin materials on the middle stream side, and films on the downstream side, as well as manufacturing that supports them. This can be seen as the tendency of applications without big holes such as technology. As a result, they have built a patent portfolio that protects the core basic patents with numerous improved patents and peripheral patents.

Applying for such patents is effective in restraining competitors and is advantageous for future applications for peripheral patents. One can say that because of the success of such a strategy, the company has not received any serious patent proceedings from home and abroad.

Technology area of TBM’s patents

3. Biodegradation, a newly developed area, is highly evaluated.

Looking at the contents of the patent application in detail, the newly developed area of TBM is biodegradable resin. In this field, Toray has the highest number of applications globally with 109 (family basis), while TBM has 29 (same) with 13th place, and other companies have generally peaked out. TBM has an increasing number of recent applications. This research and development is one of the reasons that led to the capital and business alliance with SK Group, Seoul, South Korea.

TBM’s dedicated and energetic work in IP management was recognized on April 11th,2022 when the company received the “Award for Excellent Companies Utilizing the Intellectual Property Rights System”, one of the METI Minister's Awards for Intellectual Property Achievement.

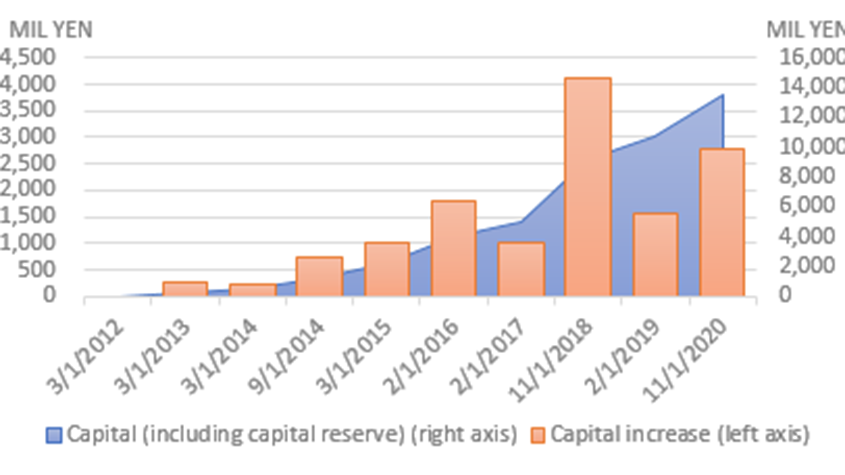

Contribution of leading patents in financing

In general, it is difficult for a venture company to obtain such a patent globally because it requires a large amount of money. The existence of a good patent group of TBM would not have been possible without the financing that made it possible, but it can be said that it is the result of a good spiral of patent strategy that made it possible.

To date, TBM has successfully raised capital of more than 23.4 billion yen, making it one of the largest domestic venture companies. In July 2021, it announced a capital and business alliance with SK Group of South Korea worth 13.5 billion yen.

According to the NEXT Unicorn Survey released by the Nikkei newspaper on December 3, 2021, the estimated corporate value was 133.6 billion yen, ranking fourth.

TBM Capital Raising

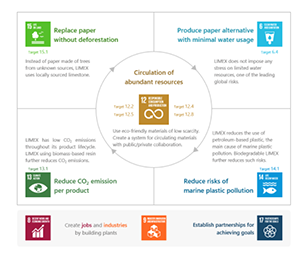

TBM Active involvement in SDGs

TBM focuses on and actively contributes to 8 core goals:

- SDG 12 "Responsible Consumption and Production",

- SDG 6 "Clean Water and Sanitation",

- SDG 13 "Climate Action",

- SDG 14 "Life Below Water",

- SDG 15 "Life On Land",

- SDG 8 "Decent Work and Economic Growth",

- SDG 9 "Industry, Innovation and Infrastructure,"

- SDG 17 "Partnership for the Goals”.

TBM mapped the relevance of each stage in the value chain to the 169 targets of the SDGs and identified the points of contact between the business and the SDGs. In the mapping exercise, they analyzed from both sides the impact of the TBM value chain on the SDGs and the impact of trends surrounding the SDGs on the TBM value chain, and arrived at the eight goals as core goals that the TBM business can have a particularly large impact.