New Packaging for Fruits and Vegetables Extends their Shelf Life in Thailand

Storing and transporting fresh fruits and vegetables is a global concern but critical for exporting countries such as Thailand. A Khon Kaen University professor developed innovative plastic bags that could extend the shelf life of produce compared to current products.

Associate Professor Somjai Kajorncheappunngam was a curious child. With no definite idea of which studies she should pursue, she followed her inclination and became a scientist. She graduated with a PhD in chemical engineering from West Virginia University before returning to Khon Kaen University to teach and undertake research.

While at West Virginia University, she focused her research on plastic composite, polymer mixed with other property-enhancing ingredients. Back at Khon Kaen University, she concentrated on plastic bags that could extend the freshness of fruits and vegetables. Thailand, she explained, is an agricultural country that exports a lot of vegetables and fruits.

After being harvested, fruits and vegetables are still alive and breathing as their metabolism continues. This process affects the taste and texture. Over some days, this process slows down, and vegetables and fruits undergo a molecular breakdown and then rot.

Modified Atmospheric Packaging

There are different methods to keep the lifespan of produce. Refrigerators or chillers were first used to keep fruits and vegetables at low temperatures. Later, scientists developed Modified Atmospheric Packaging (MAP). MAP modifies the composition of the air contained in the packaging using a mix of gases, including oxygen, carbon dioxide, and nitrogen, to extend shelf life.

The issue with MAP, she said, is that the composition of the gas mix varies according to different vegetables and fruits. The exact gas mixture composition has to be explored for each product. MAP uses synthetic plastics such as polypropylene (PP), polyvinylchloride (PVC), and polyethylene (PE), which have very low permeability.

Rice Husk Bioplastic Bags for Better Food Conservation

Prof. Kajorncheappunngam’s research focused on increasing the permeability of plastic bags using additional particles. She worked on the particle content and the stretching qualities.

She chose to use rice husk ash as the additional ingredient. “We have a tremendous quantity of rice husk coming from rice mills as waste,” she said. When rice husk is burned to ash under controlled conditions, it delivers reactive amorphous silica, commonly used as a raw material for manufacturing silicon-based materials.

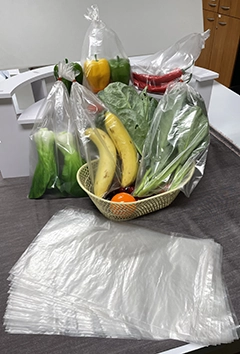

After determining the optimum quantity of rice husk particles, she began testing her plastic bags on Bananas, Bok choy, and Chinese kale. She discovered that her innovation could extend their shelf life beyond current plastic packaging.

Guaranteeing Food Safety during Transportation

Preserving the freshness of vegetables and fruits is very important for farmers exporting their products, and the MAP method is not available for most of them as they lack the technical ability to use different gas mixes.

She said that by modifying the rice husk ash particle content, she could produce plastic bags with various permeable properties to be adapted to many kinds of vegetables, adding that her method adds value to rice husk.

Slightly more expensive than regular plastic, Prof. Kajorncheappunngam said her innovation can, however, be produced on the same equipment that delivers general plastic bags, avoids the cost of the gas and the research to find the suitable composition of the gas mixture, and offers better results in terms of freshness preservation.

Tech Transfer Key for the Patented Bio-based Polyethylene Invention

The Khon Kaen University owns a petty patent (TH 8649) on “Low-density Polyethylene (LDPE) film containing Rice Husk Ash (RHA) for extending the shelf life of fruits and vegetables” and applied for a new petty patent on an improved version of the polyethylene film recently.

Prof. Kajorncheappunngam had to overcome practical issues to develop her invention, such as the lack of adequate equipment in the university to process the ingredients and produce the bags. She had to rely on a private company that manufactured the bags during its off-peak periods, slowing the experiment process.

The university is reaching out to some private companies to license the technology, although some have shown reluctance.

A Step Closer to Commercializing Bioplastic Bags in Thailand

According to Prof. Kajorncheappunngam, her plastic bags could be an advantageous replacement for the Thai export market. In a time when people have little time to go shopping, her bags can also save customers trips to shops while guaranteeing them that the products in their fridge will retain their freshness, she said, hoping her bags can be mass-produced soon.

The Khon Kaen University was supported through a collaboration between WIPO Innovation and IP Ecosystem Sector, the WIPO Division for Asia and the Pacific, and the Korean Intellectual Property Office under the Funds in Trust of Korea (a contribution made by Korea to WIPO to finance technical assistance and human capacity building projects to developing countries).

The university received patent strategy advice, leading to the new petty patent application (2403000384), and support in prototype development, bringing it a step closer to the commercialization of Thai technology.

Bioplastic for Sanitary Products and Biodegradable Plastic Bags

Newly retired from Khon Kaen University, Prof. Kajorncheappunngam continues her research work. She would like to start experimenting with a wide variety of produce and has further applications for her invention, such as using her plastic film in sanitary towels or diapers, to keep the moisture away from people’s skin.

This research, however, is conditioned by grants and investors’ interest.

In the future, she considers researching the development of biodegradable plastic bags but must overcome the fact that most biodegradable materials lack strength.