Background

The Biotech Queen from Bangalore, India’s First Lady of Biotech, the Mother of Invention; these are just some of the titles the press has coined to describe Ms. Kiran Mazumdar-Shaw, chairman and managing director of Biocon, Ltd. (Biocon), India’s largest biotechnology company. As a student, Ms. Mazumdar-Shaw had planned to become a brewer, following in her father’s footsteps. An unusual career choice for someone from the state of Gujarat (which prohibits alcohol), she returned from completing her university studies in Australia to find that the brewing industry was not ready to accept a woman.

Undeterred, she turned her interest in fermentation science to other ends. In 1978, she persuaded a small Irish company to form a joint venture, and Biocon was born. Initially working out of her garage with only a handful of rupees, Ms. Mazumdar-Shaw’s fledgling company focused on making enzymes for industrial applications, the first of which was papain, an enzyme extracted from the papaya fruit which prevents chilled beer from turning hazy. The company continued to grow through manufacturing enzymes and enjoyed much success, quickly branching out into other sectors of the biotechnology industry.

In 1989 Biocon’s Irish partner sold its ownership to Unilever, and in 1998 Ms. Mazumdar-Shaw and her husband bought out Unilever’s share. Biocon has evolved from its humble beginnings into a fully integrated biopharmaceutical company encompassing a balanced business portfolio of products and research and development (R&D) services, with a special focus on diabetes, oncology and auto-immune disease.

Invention

papaya fruit

Although Biocon’s early success was attributable to its enzyme manufacturing, the company’s big breakthrough came in the 1990s, when it invented a new fermentation technology to replace the conventional tray-based culture of microorganisms. Fermentation of enzymes is at the core of biotechnology and is a required process in the development of most biopharmaceutical products to make them suitable for human use. There are two main ways to ferment enzymes: by using a solid substrate (the surface on which an enzyme lives and reacts with) or a submerged substrate. Solid substrate fermentation has traditionally been used to manufacture fermented food products such as soya sauce and sake (a Japanese alcoholic beverage). In the biotechnology industry, most companies use submerged substrate fermentation as it is a superior fermentation technology in terms of automation, containment and large volume production.

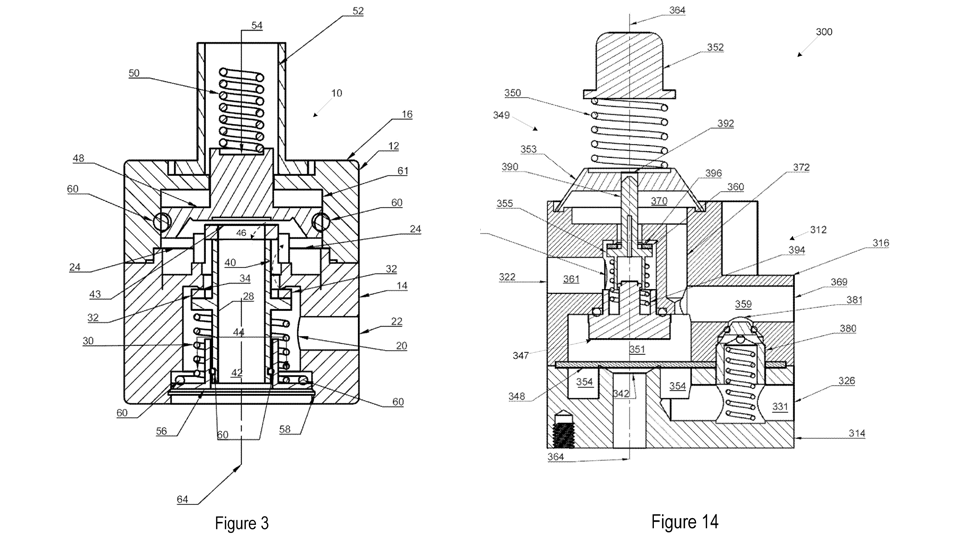

The problem with submerged substrate fermentation is that it can be a prohibitively expensive procedure, especially for startups and companies in developing countries. Recognizing the need for a more cost-effective solution, Biocon capitalized on its experience with enzyme manufacturing and in 1990 started a R&D project to innovate a bioreactor capable of conducting solid substrate fermentation with comparable levels of automation and containment as those in submerged substrate fermentation. After eight years of R&D, the company developed PlaFractor, a cost-effective bioreactor which enables all the different stage processes involved in the cultivation and extraction of microorganisms to be carried out within a fully enclosed system and under precise computer control.

PlaFractor makes fermentation repeatable, predictable and reliable. It requires less equipment and floor space than older solid substrate fermentation technologies, conserves energy, and is not labor intensive. All of these qualities translate into a cost-effective product that meets international standards and yields the same quality results as more conventional and expensive technologies. The innovation of PlaFractor served as a technology bridge, allowing Biocon to cross from industrial enzymes into biopharmaceuticals. With it, Biocon was able to begin R&D in other areas such as immunosuppressants (used to reduce rejection risks of organ transplants), which are particularly difficult organisms to cultivate using conventional tray culture.

Research and Development

Biocon’s R&D efforts are at the heart of its product innovation, and it focuses on the entire drug development pathway, from process development to non-clinical and clinical research. The depth and breadth of the company’s technological and scientific expertise enables it to develop new and affordable solutions for the world’s most debilitating diseases. Integral to the company’s success, R&D is undertaken to develop products for the company and as a commercial service. To that end, all R&D is carried out by the company’s two wholly owned subsidiaries: Syngene International Limited (Syngene) and Clinigene International Limited (Clinigene), which complement the company’s overarching R&D philosophy and business strategy. Syngene offers synthetic chemistry and molecular biology R&D services for early stage drug discovery and development, while Clinigene conducts clinical trials and studies for novel and generic molecules for Biocon and other international pharmaceutical companies.

fermentation to innovate new products

The company’s R&D efforts are organized into three principal groups: process sciences, non-clinical research and clinical research. First, the process science group focuses on developing processes for biological products (such as Insugen™), fermentation of small molecules and chemical synthesis to improve existing products and introduce new ones. Second, the non-clinical research group focuses on toxicology and pharmacology studies to provide product safety assurance. Lastly, the clinical research group develops clinical protocols for newly developed products and assesses the safety and efficacy of such products in clinical trials.

Patent Information

Using patent information is an integral tool that Biocon uses to determine which areas the company’s R&D should focus on. One such example is how the company used patent information to gain initial access to the field of human insulin production, where it is now a major player. The product patent on human insulin had long expired, but it was still protected by strong patents on processes of production. In search of a gap that would enable the company to gain a foot-hold in the market, Biocon went through all relevant published patent documents. “We noticed that most of the patented processes used e-coli and baker’s yeast,” Ms. Mazumdar-Shaw explained. “At Biocon we had expertise in another sort of yeast, and we had already licensed the intellectual property (IP) for it from a small company in the United States. So the way was clear. We started making our own insulin using pichia yeast. This was a new and unique process, which wasn’t covered by any of the existing patents.”

The resulting product was Insugen, which was released in India in 2004. As of 2010, Insugen is sold throughout the world, including in international markets such as China and Germany. It was the world’s first human insulin to use pichia yeast, which is the world’s first recombinant (artificial DNA, or r-DNA) human insulin. Insugen allowed Biocon to enter the insulin market in India – which holds 25% of the world’s population living with diabetes – and also start the company’s efforts in treating diabetes, which is a central focus of the company’s strategy. Biocon eventually hopes to develop orally administered insulin, a dream which is close to the heart of Ms. Mazumdar-Shaw. Through using patent information, Biocon was able to take the first steps towards realizing this goal.

Patents

In 1999, Biocon filed its first international application with the Patent Cooperation Treaty (PCT) system for the company’s PlaFractor innovation, with protection granted by the European Patent Office (EPO) in 2005. In 2004, Biocon filed a patent application for Insugen with the Intellectual Property Office of India (IP India), which was granted in 2010 (patent number 239944). By 2010, Biocon had filed over 900 patent applications worldwide, including over 100 PCT applications, with nearly 200 patents granted covering technology areas of fermentation, protein purification, drug delivery systems and biotherapeutic molecules. In 2008, Biocon filed a PCT application for its orally administrable solid pharmaceutical composition and process innovation to be used in connection with the development of an oral insulin product.

Trademarks

The company’s brand names are very important to maintaining its strong reputation and customer recognition, so it registers trademarks for nearly all of its commercialized products and processes. Trademarks are registered nationally and internationally, and are also registered under the name of Biocon’s subsidiary companies, such as its Insugen product, for which Biocon’s subsidiary AxiCorp registered a trademark under the international Madrid system.

Branding

While it can be a slow process, branding is an important part of Biocon’s IP strategy. The company follows a policy of ensuring that its brands convey the company’s values: innovation, quality, reliability, distinctiveness and an international outlook combined with pride in being an Indian company. This is reflected in the presentation of the company’s products, publications, website and public statements. The pale blue packaging of Biocon products was chosen to be subtle while standing out among the deluge of standard white packages on pharmacy shelves. The company name is also easy to remember and works well in international and domestic markets.

Commercialization

Biocon has an impressive track record of commercializing its products and has brought to the market a considerable portfolio of biopharmaceuticals. After the early success of the commercialization of PlaFractor, Biocon developed and marketed a strong line of statins (a drug used to lower cholesterol), insulin, and immunosuppressants, which continue to be staple products for the company. The company markets a basket of branded drugs in India, including Insugen. In 2006, the company launched BIOBab-EGFR, a revolutionary therapeutic drug used to treat cancerous tumors in the head and neck. This innovative drug was engineered to target and block the epidermal growth factor receptor (EGFR) that is responsible for the proliferation of cancer cells. These successes are examples of Biocon’s advanced process development, manufacturing and commercialization expertise.

For most international commercialization, the company traditionally partners with companies in the biopharmaceutical industry to commercialize its products in specific markets. In some cases, Biocon will buy a majority stake in such a company to have greater market access and control over commercialization activities. In February 2008, the company did just that when it purchased a majority stake in AxiCorp GmbH (AxiCorp), a German-based pharmaceutical marketing company, to market Biocon’s products in Germany and other European countries. The company has a total of five subsidiaries, three of which are involved in commercialization activities: AxiCorp; Biocon Biopharmaceuticals Private Limited, which markets Biocon’s monoclonal antibodies and cancer vaccines; and NeoBiocon FZ LLC, a research and marketing pharmaceutical company based in Abu Dhabi that was formed in January 2008 as a joint venture with Dr. B.R.Shetty, the managing director of NeoPharma, Abu Dhabi.

Partnerships

Biocon is involved in many partnerships to commercialize and market its products, as well as to develop new products. Partnerships based on IP sharing are an important part of the company’s overall business strategy. “Sharing IP is the way to develop business very fast in today’s world,” says Ms. Mazumdar-Shaw emphatically. “I don’t mean just buying it, but really sharing it. We have something another company needs; and they have something we need. Put it together and you have this powerful and very exciting synergy.”

One example of IP sharing partnerships is Biocon’s efforts to develop orally administrable insulin, which it dubbed IN105. This program was kick-started when Biocon scientists spotted an interesting patent held by Nobex, a small company based in the United States, which was related to a technology for the oral delivery of peptides (a compound made of two or more amino acids). This directly complemented what Biocon was trying to achieve, and a mutually beneficial partnership was formed. The project is close to the heart of Ms. Mazumdar-Shaw: “Just imagine if the world’s diabetics could get their insulin in tablet form instead of having to inject it. Think what a difference that would make to them each day.” In 2009, Biocon received regulatory permission to commence Phase III clinical trials (multisite trials on patient groups of 300 to 3,000) of IN105.

In May 2010, the company entered into another important partnership through a long term agreement with Optimer Pharmaceuticals (Optimer), a biopharmaceutical company based in the United States, to manufacture the active ingredient in Optimer’s new antibiotic to treat colon infections.

Biocon’s partnership philosophy combines the company’s expertise in clinical research and manufacture of biopharmaceuticals with patented technologies of its partners, thus co-developing new IP and subsequent products.

Licensing

Licensing is an important and necessary part of Biocon’s partnerships and collaborations, and it licenses in or licenses out technology and IP for R&D projects. Licensing activities tend to focus specifically on the development of monoclonal antibodies (antibodies that are the same because they are made by identical immune cells that are clones of a unique parent cell) and other novel proteins based on drug delivery systems.

IP Management

According to Ms. Mazumdar-Shaw, IP has been a factor in the success of Biocon since the company’s start. “To begin with, when Biocon was just part of a small company trying to compete in international markets, it was really just a matter of where I could sell the products, of our freedom to operate. But after Unilever bought the company, we entered this highly professional world where the role of IP was very acute. We were creating very novel IP and I started then to see just how valuable this was,” she explains. This early realization has stayed with the company, and as the company continues to strengthen its knowledge base through R&D and innovating new products, IP protection is integral to its survival.

Ever since first using the PCT system to patent PlaFractor, PCT applications have been a vital part of Biocon’s IP management strategy. “Patenting is an expensive business,” says Ms. Mazumdar-Shaw, “So you have to be very strategic as to how you go about it. The PCT lets you file, and then take some time to decide in which countries it’s worth pursuing commercially. And in the meantime it gives you a priority position and lots of protection.”

Besides PCT applications, the company also protects its IP through national application in major markets such as India and the United States. When choosing what IP will be protected, the company undertakes IP analysis to make strategic decisions as to where and when protection will be applied for while taking into account cost benefit ratios. IP analysis is an important tool used to actively support the company’s R&D and marketing strategies. All generated IP is either owned completely by Biocon or shared with its partners.

Social Issues

The entrepreneurial spirit that launched Biocon to success has also been matched by a keen sense of corporate responsibility. Rural health care in India is a particular problem, and Ms. Mazumda-Shaw points out that “One of the biggest factors of rural indebtedness in India is illness. It leads to bankruptcy and suicidal debts.” These concerns led Biocon to set up various assistance programs, such as vaccination camps, a network of free clinics in outlying areas and health education camps. Under the direction of Ms. Mazumda-Shaw, the company is also pioneering a low cost rural health insurance scheme that will provide access to quality healthcare and medicine.

Business Results

biotech company. Kiran

Mazumdar-Shaw started out

brewing enzymes in her garage.

Biocon has gone from a small startup in a garage to a billion dollar business employing over 4,000 people. For the first quarter ending June 30, 2010, Biocon’s revenue increased by 33% to over US$ 140 million compared to the previous year, and the company is forecast to enjoy continued growth. In 2004, Biocon became only the second Indian company to cross a market capitalization of US$ 1 billion on its first day of listing on the Indian stock exchange. In 2007 it was ranked as the twentieth most leading biotech companies in the world and the seventh largest biotech employer in the world.

The company has also been the recipient of many awards, the most recent of which were the Bio-Excellence Award for Outstanding Achievement in the Healthcare Sector at Bangalore India Bio (India’s largest national biotechnology event) in 2010 and the BioSingapore Asia Pacific Biotechnology Award for Best Listed Company in 2009. Ms. Mazumdar-Shaw’s role in transforming the company has also been recognized on numerous occasions. She received the Padmashri (1989) and Padma Bhushan (2005) awards presented by the President of India for her pioneering efforts in industrial biotechnology, the Technology Pioneer Recognition award in 2000 by the World Economic Forum, Ernst & Young’s 2002 Entrepreneur of the Year Award for life sciences and healthcare, the 2004 Economic Times Businesswoman of the Year award, and the 2004 Hewitt award for Best Employer of India.

IP Protected Innovation – A Foundation for the Future

From the start, Biocon was built with innovation backed by strong IP protection. The company’s innovations continue to help it grow on the one hand and bring many positive social implications on the other, all made possible by IP. Talking about the company’s goal to develop oral insulin, Ms. Mazumdar-Shaw explains that “If I can deliver oral insulin to India at a level people can afford, then I will have done my job. Without patents, I couldn’t do it at all.”