Background

keyboard

With the increasing miniaturization of electronics, the potential for developing electronic fabrics has attracted considerable attention worldwide. Promising progress has been made in this field but one major challenge faced by many researchers is the question of maintaining the flexibility of fabrics while at the same time incorporating electronic components within them. A whole new world of “intelligent textiles” opened up when two university academics, Dr. Stanley Swallow and Asha Peta Thompson, created a process of weaving complex electrical circuits into conductive fabrics such as cotton, wool and polyester. Their invention opens up a vast arena of possibilities through embedding complex technologies in both special purpose costumes and everyday clothing.

Inventions

The innovation took place at Brunel University in West London. Stanley was a lecturer and Asha was a research fellow at Brunel. They teamed up to research and develop products for disabled people at the University’s Design for Life Center. Stanley combined his expertise in electronics with Asha’s weaving and knitting skills to develop a fabric with sensors, initially designed for assisting cerebral palsy patients’ access to computers.

Whereas previous technologies involved fusing multiple layers of cloth, Stanley and Asha’s fabric is a flat piece of cloth that looks like any other. Woven with conductive fibers and connected to an energy source such as a battery, the fabric can, for example, incorporate heating elements to warm a glove; or sensors that respond to pressure transforming a piece of cloth into a computer keyboard.

Patents

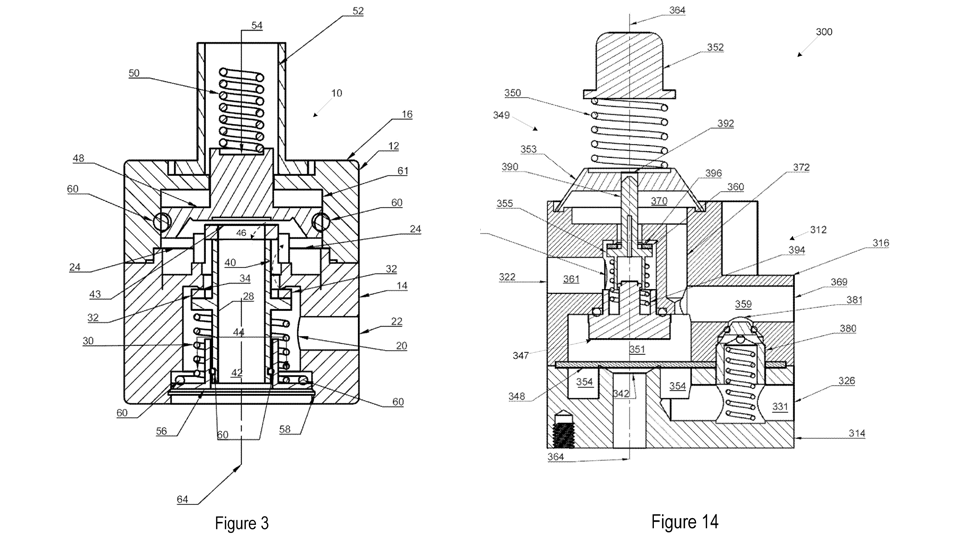

Following the development of the sensory fabric, the University patented the product in the United Kingdom. In accordance with the University’s intellectual property (IP) policy, the patent rights were owned by the University and not the inventors. The inventors, however, were involved in the patenting process. Even though Brunel supplied a patent attorney, the inventors themselves spent some six months drafting the 30-page patent application, conducted their own novelty search for conflicting patents in addition to searches by professional providers, and consulted outside patent attorneys to be sure they were getting the best advice from the University’s expert.

After several years of work at the Design for Life Center, Asha and Stanley unanimously concluded that they have exhausted their research potential within a university set-up, and decided to create an independent company for their product. They felt that although the university could provide further research and development opportunities in different areas, the technology’s potential might prove too big for the institution to handle. They needed to commercialize the product quickly. At the same time they understood that they needed to acquire the intellectual property rights (IPRs) of the product in order to further develop it. After a prolonged negotiation with Brunel, the inventors successfully convinced the University authorities to sell the patent rights to the original inventors. In 2000, Asha and Stanley bought back the rights, emptying their savings accounts and borrowing from family and friends to do so.

Trademarks

When the inventors established a company in 2002, they started looking for a name, making sure that their selected name was unique and available. After some detailed searches, they registered the name “Intelligent Textiles Limited (ITL)” as the company name. They also protected it as a trademark to ensure ownership.

IP Management and Patent Information

to prevent pressure sores

From the start, Asha and Stanley viewed IP protection as a basis for their business development. Shortly after establishing ITL, they started looking for an IP agent, and eventually recruited the patent attorney originally assigned to them by the university, because of his enthusiasm for the technology and his familiarity with a wide range of industries and IP filings.

ITL decided to expand the patent’s reach by filing international patent applications under the Patent Cooperation Treaty (PCT) and regional applications with the European Patent Office (EPO). Patent applications have also been made in the United States and Canada. Today, the company owns 17 patents in two families, as well as a few trademarks. ITL has spent more than £ 100,000 (US$ 185,000) on IP filings and protection, not including the initial cost of buying the patent from the university. The company continues to spend as much as £ 40,000 (US$ 75,000) per year on IP-related issues.

Asha and Stanley still do much IP work in-house to save money, and because they prefer to remain closely involved in this critical part of their business. They draft the documents, while the patent attorney checks and files them. Stanley himself spends time scanning the EPO’s database by keywords, inventor names and company names to check for infringement of ITL’s patents, the movements of competitors, and for inspiration.

Commercialization

Intelligent Textiles operates out of a two-room studio near London, with sewing machines on the desks and a wooden loom in the corner. Three part-time staff do technical, administrative and sales work. Its handful of customers includes a clothing company, which makes a jacket with Intelligent Textiles’ technology in the sleeve to control an MP3 player. The technology is also used in an easy chair that reclines at the squeeze of the armrest; and in foot-warming insoles for shoes and ski boots. The founders also sell their know-how through consulting contracts to a range of industries in Europe and the United States. While sales volumes are modest, the potential is huge.

Although venture capitalists have offered money to expand the company, Asha and Stanley have preferred to keep the business small and grow sales organically. This has meant outsourcing what they do not have time to do themselves. Having cut, sewn and tested the first 10,000 units themselves, they now outsource manufacturing to an English firm.

Business Results

The combination of two different areas of specialist knowledge proved to work well for Asha and Stanley. Their smart textile started in consumer apparels (for example, a wearable music player) and grew to cover medical uses (such as a pollen detector for allergy patients) and heating (heated gloves or shoe soles). Recently, the Ministry of Defense of the United Kingdom awarded ITL a research grant for developing textiles for military purposes: a wearable personal area network, radios, etc.

Asha and Stanley’s company, despite being small, is faring well in terms of returns. IP protection gives them an upper hand while dealing with customers: the filing with the EPO gave them an unexpected advantage during negotiations with their first customer, Australian Wool Innovation. "It was stated in no uncertain terms that had our patent only been granted by Australian authorities instead of the European Patent Office, it wouldn’t have been valued nearly as highly," says Asha. The resulting contract was large enough to fund further development and to pay back family and friends. The company has been operating on cash flow ever since.

Successful Use of IP for Retaining Market Position

The inventors have retained ITL’s market position through a first-to-market strategy combined with strong management of its IP. As the company continues to grow, the importance of its intellectual assets are even greater: “Without our patents,” says Asha, “we probably wouldn’t have a company.”