By James Nurton, freelance writer

Airbus, the world’s biggest aircraft manufacturer, is developing a variety of initiatives to tackle climate change. The results will not just benefit the aviation industry, but other sectors too.

Tackling climate change has become a priority for the aviation industry worldwide. It is estimated that aviation currently accounts for up to 3 percent of carbon dioxide (CO2) emissions, but with air travel expected to double every 15 to 20 years, action needs to be taken now to make future air travel more environmentally friendly.

The aviation industry is complex, with many private and public sector participants, including commercial airlines, private jet operators and government agencies, as well as manufacturers and suppliers of aircraft, engines, parts and associated infrastructure.

The intellectual property system promotes innovation and the development of new technology. Firstly, by protecting the investment in green innovation, for example, through patents, which give exclusive rights to the inventor. Secondly, by enabling the dissemination of technology assets through licensing, patent publication, joint R&D and other forms of collaboration.

Carsten Sprenger, Senior Legal Counsel, Airbus

This means that licensing and technology transfer have an important role to play in ensuring that the benefits of innovations to tackle climate change are shared across the industry. Many of these innovations have applications beyond the aviation industry and through effective use of intellectual property (IP) rights, can be licensed to other companies in completely different fields.

As the world’s biggest aircraft manufacturer, producing both civil and military aircraft worldwide, Airbus is leading the way in helping the industry develop and commercialize new technologies that support its environmental goals. As the company states on its website: “The future of flight is electric, autonomous and zero-emission. At Airbus, we believe innovation can contribute to a more sustainable world. By taking an unconventional approach to the challenges of today, we can build the sustainable aviation of tomorrow.”

The company has already contributed to progress in reducing the noise and emissions produced by recent models of aircraft. For example, the A350 XWB offers a 25 percent reduction in fuel burn and CO2 emissions compared to previous generations of aircraft. Similarly, the A330neo brings a 25 percent advantage in fuel burn per seat compared to previous aircraft in the same class.

Airbus is leveraging emerging technologies to pioneer the future of flight. By testing disruptive aircraft configurations, Airbus is able to evaluate their potential as viable future products.

Jean-Brice Dumont, Executive Vice-President of Engineering, Airbus

Looking ahead, Airbus is investing in research and development (R&D) in various areas such as cleaner technology (including electric power), materials and solutions. The results could be seismic for the aviation industry. At the Singapore Air Show in February 2020, the company unveiled a scale model technological demonstrator (2 meters long and 3.2-meters wide) for a curvaceous aircraft called MAVERIC (Model Aircraft for Validation and Experimentation of Robust Innovative Controls). The blended-wing design could cut carbon emissions by 20 percent compared to current single-aisle aircraft. Unveiling the MAVERIC, the company’s Executive Vice-President of Engineering Jean-Brice Dumont said: “Airbus is leveraging emerging technologies to pioneer the future of flight. By testing disruptive aircraft configurations, Airbus is able to evaluate their potential as viable future products.” He added, “We need these disruptive technologies to meet our environmental challenge. It is the next generation of aircraft; we are studying an option.” According to Mr. Dumont, the MAVERIC could be “instrumental in bringing about change in aircraft architectures for an environmentally sustainable future for the aviation industry.”

Did you know?

In the last 50 years, the aviation industry has:

- cut fuel burn and CO2 emissions per seat/kilometer by more than 80 percent;

- reduced NOx emissions by 90 percent;

- lowered noise levels by 75 percent.

By 2036, air traffic is set to grow by 4.4 percent per year and it will be necessary to build 35,000 new aircraft to meet that rise in demand for air travel (Airbus Global Market Forecast).

Making aviation sustainable

In line with commitments outlined in the 2015 United Nations Climate Change Conference (the Paris Agreement), the Air Transport Action Group (ATAG), an independent industry-wide body that promotes sustainable growth, has set out three environmental goals. The first is to improve global fleet fuel efficiency by 1.5 percent per year from 2009 to 2020. This goal has already been achieved with more than a 2 percent CO2 reduction throughout the period. The second goal is to cap net CO2 emissions starting in 2020 through carbon offset measures, and the third is to ensure that CO2 emissions in 2050 are half what they were in 2005.

These goals are underpinned by five pillars of climate action: technological innovation; operational improvements; infrastructure efficiencies; sustainable aviation fuels; and market-based measures to offset growth in CO2.

IP rights have an important role to play in achieving the goals, in particular in promoting the development of new technologies to make aircraft more efficient and exploring the use of alternative fuels.

The intellectual property system promotes innovation and the development of new technology. Firstly, by protecting the investment in green innovation, for example, through patents, which give exclusive rights to the inventor. Secondly, by enabling the dissemination of technology assets through licensing, patent publication, joint R&D and other forms of collaboration.

“Airbus considers the existing IP system to be well prepared to incentivize green innovation. Under the existing IP system, IP strategies can be well adapted to support environmental/green objectives,” Mr. Sprenger says. He adds that IP rights are also important in making innovation available across different industries: “In particular for sustainable technology, IP rights enable the access to such technologies across different sectors and industries worldwide.”

Areas of innovation

Airbus is a highly innovative company, with an annual R&D budget of some EUR 2 billion, self-financed R&D investments totaling EUR 3.4 in 2019 and more than 1,000 scientists and researchers worldwide. In total, the company holds about 37,000 patents across a wide range of technologies. “Many of Airbus’ technical developments in the field of green innovation are protected through patents,” says Mr. Sprenger.

Current areas of focus for the company include:

Sustainable aviation fuel (SAF): Airbus is studying how synthetic fuel using renewable energy could be a substitute for kerosene. This fuel could be made from recycled materials such as used cooking oil, agricultural residues or municipal waste and could reduce CO2 emissions by 80 percent. The company has offered delivery flights powered with SAF since 2016 in Toulouse (France), Mobile (USA) and Hamburg (Germany). In September 2018, Airbus became the first industry member of the Hydrogen Council. In December 2019, it started to introduce SAF to power its industrial transportation needs.

Electric and hybrid-electric: Airbus has been developing these systems since 2010 and in November 2017, launched the E-Fan X, a hybrid electric demonstrator, in partnership with Rolls-Royce. It is expected to make its first flight in 2021. Airbus has also developed two vertical take-off and landing demonstrators called Vahana, an all-electric, single-seat, tilt-wing vehicle, which has flown over 80 test flights to date, and CityAirbus, an all-electric, four-seater multicopter, which conducted its first take-off in May 2019. Autonomous flying taxis of the future perhaps? In 2018, its solar-powered high-altitude pseudo-satellite called Zephyr set the longest flight duration record of any aircraft. It promises to revolutionize defense, humanitarian and environmental missions across the globe.

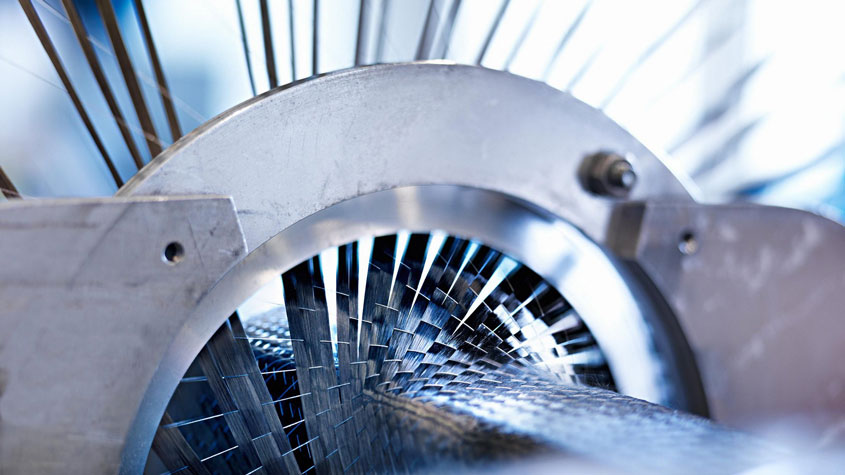

New eco-efficient materials: Airbus is considering a diverse range of materials, which include lightweight and functional composites, such as Carbon Fibre Reinforced Plastic (CFRP), which offers greater fatigue and corrosion resistance, and therefore longer in-life use than traditional metallic materials and has significant weight and fuel saving properties. It is also looking at bio-sourced materials such as spider silk (it’s stronger than steel, tougher than Kevlar and incredibly lightweight), which promise to revolutionize aerospace design. It is also experimenting with advanced surfaces and coatings and ultra-high temperature materials and ceramics. These new surfaces and materials, such as tungsten carbide coating and new metal alloys, can be used on key aircraft parts such as compression flap pads and turbine blades to provide greater efficiency and replace environmentally damaging materials.

Working with partners

As well as its considerable internal R&D, Airbus works with various organizations by forming research and technology partnerships, which it sees as a way to accelerate and disseminate innovation. Examples of such partnerships include:

The Clean Sky Program, a European initiative to drive aeronautical research and innovation to make air transport more eco-efficient, as well as to strengthen the competitiveness of Europe’s aerospace industry. The program seeks to promote the development of technologies to reduce noise, lower CO2 and cut gas emissions. Airbus, a major player in the program, is leading the development of a number of cutting-edge technologies to meet established environmental targets. These include:

UltraFan, a collaboration with Rolls-Royce. UltraFan offers a 25 percent improvement in fuel efficiency over the first generation of Rolls-Royce’s Trent engine. Airbus and Rolls-Royce are working to integrate the UltraFan demonstrator for flight-testing (a project co-funded by Clean Sky), with a view to integrating the engine into future aircraft.

BLADE (Breakthrough Laminar Aircraft Demonstrator in Europe). Airbus heads a team of more than 20 partners on this project. BLADE modifies the shape, materials and surface of wings to transform commercial aviation by reducing drag by up to 50 percent. The project is also part of the Clean Sky program.

Wing of Tomorrow: Airbus’ largest research program worldwide is the product of an industry-wide partnership aimed at creating a revolutionary new structural and systems architecture for carbon wings. The project seeks to imitate the flight technique of the legendary albatross sea bird – unlike any other bird, it can soar hundreds of kilometers without flapping its wings – to design lighter and more fuel-efficient aircraft.

MOZAIC: Airbus also takes part in the Measurement of Ozone by Airbus in-service Aircraft (MOZAIC) alongside six airlines (Lufthansa, China Airlines, Air France, Iberia, Cathay Pacific and Air Namibia) by equipping seven wide-body aircraft with measurement devices to capture data such as concentrations in ozone, water vapor and carbon monoxide.

In working with partners, Airbus can make use of its patents and other IP rights, says Carsten Sprenger: “In the field of electric propulsion, Airbus is using IP rights in its transactions with R&D partners to create complementary fields of use, such as giving rights of use to Airbus for air transport and to the partner for ground transport. This supports the considerable investment some of these technologies require and fosters a broad dissemination of the results.”

Moreover, he adds, IP rights can also be licensed to other industries to ensure that the potential of the innovation is fully exploited: “We have used licensing agreements to make available technology that was originally developed at Airbus for aerospace applications to green industries like the wind energy sector.”

Evolving IP strategy

The various means of using IP rights means there is no simple answer to the question of what benefits they bring, says Mr. Springer: “There are literally hundreds of contextual use-cases [that demonstrate] how a company can use IP rights. The benefits depend always on the objectives of the IP rights owner.” He adds: “In the context of innovation for a green future, we expect that global warming and environmental issues might provoke the development of IP strategies adapted to support the technological, environmental and political aims of actors in the green technology space.”