How can health care facilities, supermarkets and data centers manage their significant and growing energy use? And how can they overcome the challenges posed by limited access to green electricity? This chapter explores innovative solutions tailored for these essential services, highlighting the critical need for benchmarks and standards to better understand and mitigate their environmental impact.

Introduction

High-demand sectors in critical need of energy reliability and resilience

Supermarkets, health care facilities and data centers, despite serving vastly different purposes, share a critical commonality: they all demand reliable, uninterrupted energy to operate effectively. These sectors are energy-intensive, outstripping most other private, commercial and public building types (

Supermarkets, health care facilities and data centers share a critical commonality: they all demand reliable, uninterrupted energy to operate effectively

They also have strict requirements for maintaining temperature control, supporting essential equipment and ensuring the safety and well-being of their users or customers. Any disruption in power can have significant consequences, from spoiled food and compromised patient care to data loss and operational downtime.

This dependency on consistent energy supply also makes them prime candidates for clean energy solutions. Integrating renewable energy sources, enhancing energy efficiency and adopting advanced energy storage technologies can not only reduce their environmental impact but also bolster their resilience against power outages and fluctuations in energy costs.

Essential but energy-intensive sectors can no longer be overlooked

Another commonality for the sectors covered in this chapter is that their energy demand is growing. Supermarkets are trending toward smaller convenience stores – which can be about half as efficient as larger ones – and more frozen food, which demands more electricity for cooling

With limited renewable energy use in many regions and fossil fuels still maintaining an 82 percent share of global primary energy production

Overcoming decarbonization challenges with decentralized energy supply

Decentralized energy systems, such as hybrid renewable energy systems incorporating solar photovoltaics (PVs) and batteries, are increasingly being adopted to provide clean and reliable energy in end-use sectors. For example, in Zimbabwe, over 400 health centers have installed solar arrays. Similarly, several supermarkets utilize rooftop solar panels and participate in micro-grids to stabilize their energy supply and reduce GHG emissions. Data centers, with their high energy demands, can benefit from modular and off-grid solutions like solar power, micro-grids and battery energy storage systems but are yet to do so on a large scale.

All these subsystems benefit from advances in intelligent energy management systems, which are essential for ensuring they work together efficiently and reliably, especially in critical situations like maintaining operations during extreme conditions such as natural disasters

Cooling and refrigeration shifting toward greener solutions

In addition to significant heating, cooling and ventilation needs, these essential services face unique challenges with regard to the need for cooling of food, hardware and medicine. Health care facilities also require higher ventilation standards. Cooling and ventilation is where much of the innovation is happening, with efficient medical freezers, subcritical CO2 boosters and liquid cooling technologies, to name a few of the technologies described in the chapters.

Simple and effective solutions like simply equipping supermarket cabinets with doors can sometimes offer the highest energy savings

New advances are further enabling better cooling efficiencies in hot and humid climates. Technologies that manage airflow and humidity in data centers and hospitals, for the benefit of heat dispersion and patient health, are becoming more sophisticated. However, simple and effective solutions like simply equipping supermarket cabinets with doors can sometimes offer the highest energy savings. Making use of natural elements, through free cooling that uses cold outdoor air or water bodies, is another promising trend that can help reduce demand for mechanical cooling.

Benchmarks and standards catching up

Energy efficiency standards and labeling schemes significantly impact the adoption of energy-efficient technologies. For instance, European Union (EU) minimum energy performance standards and energy labels reportedly increased the market share of efficient cold appliances by 15 to 38 percentage points

However, more work is needed in terms of benchmarks, coordinated action and greater transparency to fully understand their energy footprint and evaluate the effectiveness of their climate investments. For health care facilities and supermarkets, they have only recently started their sustainability journeys. The energy consumption of data centers has been understood and assessed for longer, but the general lack of transparency by privately owned tech companies means real figures are hard to come by. These findings underscore the importance of policy measures, labeling schemes and public awareness in promoting low-carbon and energy-efficient technology adoption.

Energy-efficient supermarkets

Supermarkets are among the biggest energy consumers of all commercial building types. Grocery stores, wholesalers, convenience stores and other food retailers need energy for keeping produce fresh, illuminating their shops and controlling temperatures and humidity. By adopting low-carbon energy technologies, supermarkets and other food retailers can significantly reduce their climate impact and lower energy costs.

Technological developments and trends

Supermarkets’ unique energy challenge

Supermarkets have been growing rapidly in number, having emerged in the United States of America and Western Europe in the 1920s–40s, and in developing areas in the 1980s–90s

Supermarkets are among the biggest energy consumers of all commercial building types

With the vast number of daily visitors, supermarkets can be a place of influence, facilitating green diets and sustainable sourcing of food

While the supermarket industry has been growing, earlier data indicated that supermarkets in the United Kingdom accounted for about 3 percent of national electricity consumption

Smaller supermarkets consume twice the energy of larger ones

In many countries, energy intensity in supermarkets has been reduced with the help of energy efficient technologies for lighting, refrigeration, and heating, ventilation and air conditioning (HVAC). A global trend that is hampering such progress is the growing number of smaller food stores such as convenience food shops, which also happen to have a higher energy intensity. In London, supermarkets of around 300 m2 have an energy intensity of 840–1200 kWh/m2 per year compared to larger supermarkets that average about 400 kWh/m2 annually (see box 4.1)

Another growing trend is frozen food, which performs particularly well during disruptions such as the pandemic and periods of economic turmoil. The higher the percentage of frozen food, the higher the total energy usage due to more demand for lower temperature refrigeration (

In many countries, few food retailers own a majority of the grocery stores in the country. While these are not always managed centrally, there is a certain degree of standardization of the stores

In the United States, the non-profit Ratio Institute has worked with more than 1,000 grocery stores and 20 grocery chains to benchmark their energy performance and identify store-level sustainability measures. While grocery stores within a chain try to contribute to the company’s goals for energy efficiency and reduction in climate impact, most food retail companies do no benchmarking of store-level performance against an energy or sustainability standard. Benchmarking against a performance standard helps a food retailer with many locations be systematic and ensure accountability for a store’s performance. A spectrum of high performers to low performers within a company’s suite of stores can be realized and priorities can be determined to leverage opportunities for higher efficiency. Currently, efficiency measures are being performed in a random manner that limits alignment with company goals.

The International Energy Agency (IEA), under the IEA Heat Pumping Technologies (HPT) Annex 44 project, aimed to estimate the energy consumption of supermarkets around the world. While the size of the supermarket was found to be the best performance indicator for assessing energy consumption, other common indicators for supermarkets include refrigeration system type, installed refrigerating capacity and opening hours. In a survey of larger supermarkets in countries like Sweden and the Netherlands, the average energy intensity of larger stores was estimated to be approximately 400 kWh/m2 per year. It was also found that advances in refrigeration systems and lighting could enhance energy efficiency by up to 10 percent

Various other initiatives also seek to include food retailers in the energy transition. The SuperSmart European Project aims to increase uptake of energy efficient technologies in supermarkets. Under this initiative, a European label for eco-friendly supermarkets has resulted in guidelines and best practice measures for reducing total energy use by nearly half, through technologies such as intercoolers (internal gas coolers), heat recovery to water, destratification fans, as well as CO2 refrigerators

Refrigeration the biggest energy consumer

Refrigerator systems are energy-consuming and often dependent on refrigerants with a high GWP. The type of refrigeration system adopted by a supermarket has an important impact on energy consumption, considering they account for 35 to 50 percent of the total energy use

Stand-alone plug-in cabinets, condensing units (with “split systems” connected to a remotely located condenser) and centralized systems using high-GWP refrigerants are common among supermarkets. While condensing units use more refrigerants, plug-in options often consume the most energy

Supermarket refrigeration technologies of the future

Between 2008 and 2020, the adoption of transcritical CO2 refrigeration systems in Europe grew from 140 to 35,500 systems, with 55,000 reported in 2022. In Europe, transcritical CO2 refrigeration systems have gained industry-wide acceptance, with over 18 percent of the food retail market having adopted the technology (

Between 2008 and 2020, the adoption of transcritical CO2 refrigeration systems in Europe grew from 140 to 35,500 systems, with 55,000 reported in 2022

While medium-sized supermarkets have been the main adopters of CO2 refrigeration systems, a noticeable trend involves the development of units that are suitable for smaller stores

Refrigeration systems in warmer climates

While transcritical CO2 systems were previously considered unsuitable in warmer climates due to lower efficiencies, new innovations and cost competitiveness have allowed use of CO2 refrigeration systems regardless of climate

Other efficiency-enhancing technologies which allow the use of transcritical CO2 systems in warmer climates include ejectors and parallel compression, the latter which could enhance efficiency by more than 10 percent

Compared to regular transcritical CO2 refrigeration systems, adiabatic refrigeration systems incorporate an additional cooling step to enhance efficiency, particularly in warmer climates. A study in Chile pointed to an adiabatic transcritical CO2 refrigeration system being 44 percent more energy efficient than one using a conventional R507 HFC refrigeration solution

Efficient heat recovery and simple dehumidification techniques

In supermarkets, as in most energy-consuming sectors, a significant amount of energy is lost as waste heat. The use of heat recovery from refrigeration systems is gaining traction, but still remains underutilized despite great potential for energy and cost savings

Another often overlooked efficiency measure relates to managing humidity. Humidity in supermarkets can lead to more frost formation on refrigeration coils in food display cabinets, which reduces their efficiency. Many supermarkets have not adopted solutions to dehumidify air. For those that have, dehumidification itself contributes to energy consumption, warranting a full analysis of net energy costs of the store.

Solutions can involve a combination of dehumidifiers, improved refrigeration design, anti-sweat glass doors, humidity sensors or the use of water-absorbing materials like silica gel that are incorporated in the ventilation systems

However, sometimes the solution is far simpler. In fact, studies have shown that equipping display cabinets with doors to avoid frost formation on coils can offer energy savings of almost 40 percent, which is far greater compared to other dehumidification measures

Light-emitting diodes (LEDs), daylighting and automation

Lighting represents about 13 percent of electricity consumed in a supermarket or related establishment. Compared to other investments, lighting measures such as switching to LEDs is often considered a low-hanging fruit with potential to save up to 50 percent on lighting energy

Beyond switching to LEDs and training personnel in energy efficient behavior, energy consumption can be reduced further by installing motion and daylight sensors. Automated control systems can adapt lighting to occupancy rate and opening hours of the shops. Further, placement of photoelectric cells outside to measure light intensity enables shops to reduce indoor lighting when it is dark outside. This offers more comfortable lighting as the contrast is less harsh for consumers whose eyes have adjusted to the darkness outside. Combining daylighting with artificial lighting and suitable control systems such as dimmers also helps enable a more cost-effective and efficient lighting level.

On-site energy production for food retailers

While energy conservation and efficiency measures are a priority, supermarkets and food retailers have the option of producing their own clean energy to further mitigate energy-related GHG emissions. The profitability of such initiatives is higher for larger supermarkets and is largely dependent on the price of electricity. On-site electricity production can be particularly suitable for supermarkets as they have predictable energy consumption patterns, with the only variance being whether the store is open or closed. Supermarkets also often have large parking facilities and ample space for rooftop solar.

Solar, off-site wind and geothermal energy are all options for provision of electricity, heating and cooling. However, given the excess heat generated from refrigeration and lighting systems, technologies for on-site heat production are often of low interest

Automation and monitoring systems

In modern building management, various technologies can be seamlessly integrated into building systems to achieve greater energy efficiency. Using smart meters, supermarkets can track electricity consumption at regular intervals throughout the day or in real time, enabling them to identify opportunities for optimization. Integrating such meters with building management systems can enable automated demand response programs, allowing utilities and building systems to communicate to dynamically manage electricity demand during periods. This also allows adjustment of energy-intensive activities based on peak and off-peak periods, price signals or grid conditions. Beyond energy savings, this promotes grid stability and reliability. Automation is in fact among the most sought-after technologies for supermarkets to adopt (box 4.2).

Calculation and comparisons of energy consumption is also useful for identifying the right refrigeration system. Off-the-shelf simulation tools are available to integrate load profiles and weather data to compare the performance of different refrigeration systems and configurations. Other innovations enable multiple appliances in supermarkets to be monitored and managed through an internet of things (IoT)-based solution that collect data from appliances. Supermarket kitchen equipment such as vent hoods equipped with sensors can save energy by detecting when the stove is in use, to avoid sucking out dry air throughout the day.

Supermarkets are surprisingly keen on adopting new technologies, as evident from a 2023 market report that surveyed more than 130 grocery industry professionals. While climate technologies were not specifically addressed, all respondents indicated that technology will be at least somewhat important for the future of retail, and expressed an intention to invest in the year to follow. Peer recommendations and existing vendors are prioritized, indicating a challenge for climate tech startups to introduce their products to the sector. In fact, 58 percent suggested that industry peers and networking are the main resources when looking for technologies. The adoption of most new technologies is driven by chain retailers. Further, the most sought-after technologies are those that enhance operational efficiencies through for instance automation, which often goes hand-in-hand with energy efficiency

Innovation examples

Energy-efficient refrigeration systems in Jordan

A supermarket in Jordan, with the support of the United Nations Industrial Development Organization (UNIDO) and the Ministry of Environment in Jordan, installed a transcritical CO2 refrigeration system to demonstrate the feasibility of such systems in high temperature environments. The Al Salam military supermarket in Amman was the first in its region to install this technology in 2018, using a system supplied by Italian manufacturer Enex Srl. In addition to avoiding climate-hazardous refrigerants, the CO2 refrigeration system was more energy efficient than the previously used conventional system using HFCH-22 refrigerant. A state-of-the-art ejector technology was integrated to ensure high efficiency during warm summer months. Also known as a jet pump, the ejector is a device that can use energy in a high-pressure refrigerant to compress a low-pressure refrigerant, increasing overall efficiency

Solar at South Africa’s largest retailer

The Shoprite Group, South Africa’s largest retailer with over 2,900 stores in 11 African countries, is making use of solar energy to cut operational costs. Given that South Africa’s energy grid is predominantly coal-powered, the installation of solar systems at on-site and off-site locations offers a good option for low-carbon energy supply. In 2022, solar systems had been installed at over 60 sites in South Africa and beyond, with a total installed capacity of 26.6 MW

Proven technology solutions

Energy efficiency: retrofitting refrigerator doors

Koolmax Group

The simple switch from open to closed refrigerator cases at supermarkets have shown to have a tremendous impact on energy efficiency. Rather than replacing the entire system, technology and service providers can be identified to retrofit doors onto existing display cabinets. Koolmax Group offers several designs of double glazed hinged or sliding doors that can be retrofitted onto existing cabinets.

Contracting type: For sale

Technology level: Low

Country of origin: United Kingdom

Availability: Worldwide

Contact: WIPO GREEN Database

Energy efficiency: low-E glass doors

Loreco System

Low-E glass doors can enhance energy efficiency in supermarkets as they reduce heat transfer, helping to maintain cold temperatures inside refrigeration cabinets. This special type of glass has a coating that blocks infrared and ultraviolet light while letting in visible light, which keeps the temperature more stable and results in lower energy costs. Additionally, these doors are less prone to condensation, avoiding moisture build-up and making them easier to maintain.

Contracting type: For sale

Technology level: Low

Country of origin: Spain

Availability: Spain

Contact: WIPO GREEN Database

Energy efficiency: transcritical CO2 refrigeration

SCM Frigo

SCM Frigo, an Italian manufacturer that specializes in refrigeration technologies based on the natural refrigerant CO2 has recently introduced a new line of transcritical CO2 booster systems for commercial use. The technology can be adapted with optional heat recovery as well as energy meters, and works in all climates due to a dynamic vapor injection technology which helps handle gases that typically weaken transcritical refrigeration systems.

Contracting type: For sale

Technology level: High

Country of origin: Italy

Availability: Worldwide

Contact: WIPO GREEN Database

Energy efficiency: transcritical CO2 refrigeration

Arneg Andina

Arneg offers different kinds of transcritical CO2 refrigeration systems for grocery stores of all sizes: the Globo, Globo+, Mini Booster, Booster and Booster XL. The standard systems are suitable for all climates, while those with an adiabatic post-cooler are designed for hotter climates. The other systems, either having a parallel compressor or a parallel ejector and compressor, optimize energy performance through different mechanics to address varying needs for reducing energy use. The systems also come with optional accessories for recovering waste heat or producing cold water to use in other applications in the store, such as in the HVAC system.

Contracting type: For sale

Technology level: High

Country of origin: Colombia

Availability: Latin America

Contact: WIPO GREEN Database

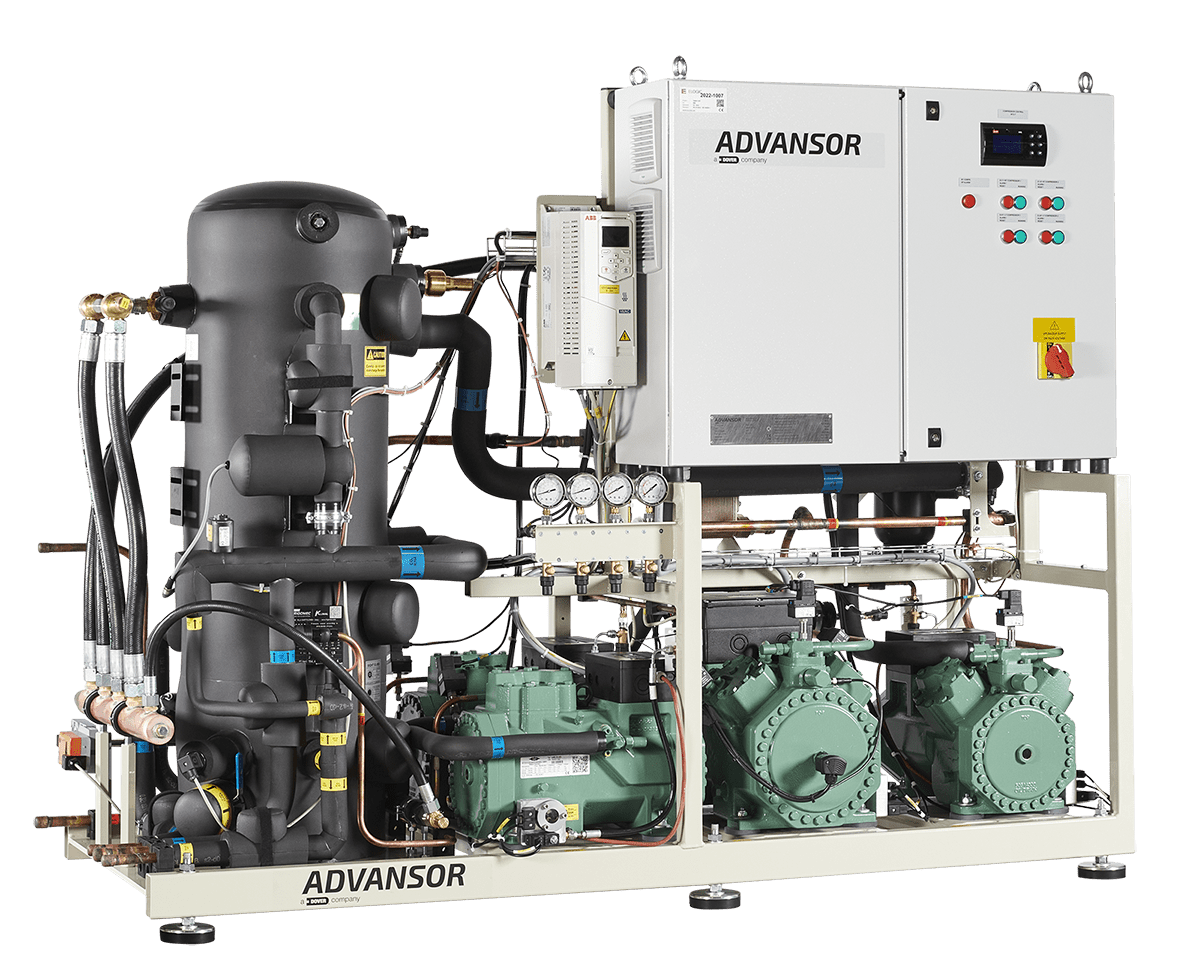

Energy efficiency: compact transcritical CO2 system for smaller supermarkets

Advansor

For smaller supermarkets with limited space, Advansor offers a line of compact transcritical CO2 refrigeration system units. They are the Value Pack (VP), VP Light, VP II and the Minibooster. At their upper ranges, these systems deliver medium temperature cooling capacities between 45 kW and 136 kW. Additionally, all systems come with optional accessories allowing for functions such as waste heat recovery.

Contracting type: For sale

Technology level: High

Country of origin: Denmark

Availability: Worldwide

Contact: WIPO GREEN Database

Energy efficiency: destratification fans

Airius

Conventional heating and cooling systems can lead to an uneven temperature distribution in supermarkets and stores, leading to warm air rising to the ceiling and cooler air settling at surface level – so-called stratification. This exerts extra pressure on the heating and cooling systems, leading to unnecessary losses. Destratification fans support air circulation in stores, providing a more consistent temperature and saving in HVAC energy costs. Company Airius provides a wide range of fans, with a specific series relevant for grocery stores.

Contracting type: For sale

Technology level: Medium

Country of origin: United States

Availability: Worldwide

Contact: WIPO GREEN Database

Energy supply: solar-powered cold storage units

ColdHubs

Solar-powered cold storage units are critical for avoiding food waste in many markets and farms. The technology is particularly relevant in rural regions in developing countries where temperatures soar high, and off-grid locations create challenging conditions for food retailers. However, urban markets can also benefit from adopting the technology to store food and reduce waste.

Contracting type: For sale

Technology level: Medium

Country of origin: Nigeria

Availability: Nigeria

Contact: WIPO GREEN Database

Energy efficiency: adiabatic subcooler for supermarket refrigeration systems

MITA Cooling Technologies

To boost the efficiency of CO2 or natural refrigerant systems, MITA Cooling Technologies offers patented adiabatic subcoolers. These subcoolers can be installed in supermarket to increase efficiency without major system changes. They are plug-and-play solutions that are added downstream of the condenser or gas cooler in CO2 chillers. In addition to energy savings, the coolers include functions such as a software for calculating return on investment as well as a compact, modular design with simple maintenance.

Contracting type: For sale

Technology level: High

Country of origin: Italy

Availability: Italy

Contact: WIPO GREEN Database

Energy efficiency: daylighting in supermarkets

Sundowner Skylights

Supermarkets can reduce their energy use and costs by installing light-capturing domes on their roofs. The Tube Skylights from Sundowner Skylights funnel sunlight directly into the indoor environment through these domes. They come with a range of diffusers to adjust for desired intensity, a built-in lamp for nighttime illumination, and an optional attachable ring to turn the light off. The skylights are compatible with a wide selection of roof types, including corrugated iron or cement tiles.

Contracting type: For sale

Technology level: Medium

Country of origin: South Africa

Availability: South Africa

Contact: WIPO GREEN Database

Frontier technology solutions

Energy efficiency: simulation tool for refrigeration systems

IPU

Pack Calculation Pro is a simulation tool for calculating and comparing the yearly consumption of refrigeration systems and heat pumps. The tools use load profiles and weather data to compare the performance of different refrigeration systems and their configurations.

Contracting type: For sale

Technology level: Medium

Country of origin: Denmark

Availability: Denmark

Contact: WIPO GREEN Database

Energy efficiency: real-time monitoring of energy consumption

Memoco

Memoco’s Energy Box has been designed to reduce energy costs in the retail sector, by giving energy operators an insight into real-time energy consumption in the shops via a web interface. The Box is also provided via a leasing agreement where the cost is recovered through the energy and cost savings made by the store.

Contracting type: For sale

Technology level: Medium

Country of origin: Belgium

Availability: Worldwide

Contact: WIPO GREEN Database

Energy efficiency: wireless sensors for supermarket temperature monitoring

Ruuvi

RuuviTag is a wireless thermometer designed for use in grocery stores and supermarkets. It allows users to monitor temperature, manage cooling and heating systems, receive alerts and review past temperature data. The device supports remote monitoring through the Ruuvi Gateway and Cloud service, providing flexibility in overseeing temperature conditions.

Contracting type: For sale

Technology level: Medium

Country of origin: Finland

Availability: Worldwide

Contact: WIPO GREEN Database

Energy efficiency: integrated refrigeration, air conditioning and heating unit for supermarkets

Daikin

Daikin’s Conveni-Pack system is an innovative solution tailored for supermarkets, combining refrigeration, cooling, heating and ventilation into one compact unit. Utilizing CO2 as a natural refrigerant with a GWP of just 1, the system is highly energy-efficient and environmentally friendly. Its CO2-specific swing compressor boosts energy efficiency by 5 to 15 percent and extends the compressor’s lifespan. The Conveni-Pack is flexible in installation, space-saving and operates quietly, making it suitable for supermarket environments.

Contracting type: For sale

Technology level: High

Country of origin: Japan

Availability: Worldwide

Contact: WIPO GREEN Database

Energy efficiency: heat recovery from refrigeration installations

Danfoss A/S

Heat is typically a by-product of refrigeration processes. By recovering this heat, supermarkets can reduce their CO2 footprint and grid-energy consumption. Danfoss offers the Heat Recovery Unit, a combined CO2 refrigeration and water heating system that captures waste heat from the cooling process to meet the supermarket’s space and water heating needs. Excess heat can also be sold to the local district heating system.

Contracting type: For sale/service

Technology level: High

Country of origin: Denmark

Availability: Worldwide

Contact: WIPO GREEN Database

Energy efficiency: actively cooled refrigerated and frozen containers for last-mile delivery

Phononic

Phononic has developed actively cooled and temperature-sensitive tote freezers and refrigerators which use CO2 as a natural refrigerant. The totes use wireless contact charging and real-time temperature insights, enabling better transportation of perishable goods for grocery stores that have adopted e-commerce. For instance, data can be used to manage demand-based energy savings by only cooling or freezing the number of customer orders needed rather than an entire cooler or transport truck.

Contracting type: For sale

Technology level: High

Country of origin: United States

Availability: Puerto Rico, United States

Contact: WIPO GREEN Database

Energy efficiency: ultra-low superheat module for supermarket refrigeration system

Advansor

Advansor’s Ultra-Low Superheat Module enhances supermarkets’ refrigeration efficiency by allowing the cooling units to operate at higher temperatures without causing them to overflow with refrigerant, using less energy. The module includes three main components: a suction accumulator, an internal heat exchanger, and an optional ejector. The suction accumulator captures any returning liquid from the units and separates it from the gas. The internal heat exchanger then evaporates and superheats the gas and liquid CO2 from the accumulator, while also cooling the liquid line. This leads to energy savings of up to 30 percent with a two-year payback time.

Contracting type: For sale

Technology level: High

Country of origin: Denmark

Availability: Worldwide

Contact: WIPO GREEN Database

Energy efficiency: demand control kitchen ventilation

Melink Corporation

Kitchen hood fans typically waste energy by operating either at full capacity or not at all, and they also expel air that has already been heated or cooled at a cost. Demand-control kitchen ventilation systems address this inefficiency by retrofitting hood fans with advanced controls that automatically adjust the fan speed based on the cooking activity. This technology lowers energy bills, creates a more comfortable environment for staff and customers, and reduces the need for “make-up air” the fresh air that replaces the exhausted air.

Contracting type: For sale

Technology level: Medium

Country of origin: United States

Availability: Worldwide

Contact: WIPO GREEN Database

Horizon technology solutions

Energy efficiency: integrated IoT-based data monitoring and management for supermarkets

Tietoevry

Tietoevry is a Finnish IT software and service company that has piloted a solution to harness the power of data for energy efficiency in a supermarket. In collaboration with retailer REWE Austria, Tietoevry transformed a store in Austria into an energy-efficient “Supermarket of the Future” by leveraging data integration. The project focused on gathering data from various store appliances, which were previously unconnected, to optimize energy use and maintenance processes. Tietoevry developed an IoT-based solution that collects and analyzes the data, presented through a user-friendly dashboard on Microsoft’s Azure platform. This system not only simplified store management but also reduced energy and maintenance costs by up to 25 percent.

Contracting type: For service

Technology level: High

Country of origin: Finland

Availability: Worldwide

Contact: WIPO GREEN Database

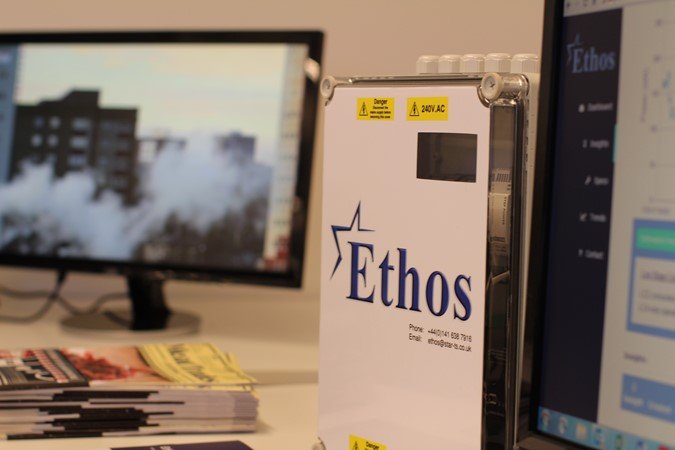

Energy efficiency: Smart energy management tool for supermarket distribution centers

Star Refrigeration

Star Refrigeration and the UK’s largest supermarket chain, Tesco, joined forces in trialing the Ethos system, an AI-driven monitoring and performance optimization system, at eight of Tesco’s supermarket distribution centers for 21 months. This achieved an average cut of 10% in energy use, corresponding to a total of 4 GWh of energy savings and an 835 tonne reduction in CO2 emissions. The Ethos system gathers and analyzes data from heating and cooling equipment to generate a cloud-based digital twin, which provides managers with detailed insights on system performance, inefficiencies, trends, as well as recommended corrective measures coupled with estimated financial and CO2 savings. The continuous monitoring and resulting insights also help with maximizing the operational lifetimes of Tesco’s refrigeration plants, further minimizing costs.

Contracting type: For service

Technology level: High

Country of origin: United Kingdom

Availability: United Kingdom

Contact: WIPO GREEN Database

Energy efficiency: Quantum computing in grocery optimization

D-Wave Quantum Inc.

In grocery retail, quantum computers can help minimize waste and carbon footprint by optimizing tasks like product placement, efficient resource use, and delivery of perishable goods. D-Wave is a quantum computing company offering a full-stack technology solution, including systems, cloud services, development tools, and professional services to benefit business and society. They help businesses identify and solve problems that benefit from hybrid quantum technologies, providing online training, professional services, and access to the Leap quantum cloud. Save-On-Foods, a leading grocery retailer in Western Canada, is piloting innovative grocery optimization solutions in their business by leveraging D-Wave hybrid quantum algorithms. A key optimization task is now being completed in just 2 minutes each week—a task that previously took 25 hours. D-Wave is exploring quantum computing applications in various fields, including optimization problems relevant to energy management and refrigeration systems.

Contracting type: Under development

Technology level: High

Country of origin: Canada

Availability: N/A

Contact: WIPO GREEN Database

Energy efficiency: Device for energy-efficient refrigeration cabinets

Aerofoil Energy

Aerofoil Energy is a technology company supplying energy solutions to grocery retailers worldwide by transforming the performance of display refrigeration, reducing energy consumption and associated emissions. Jetseal is Aerofoil Energy’s latest innovation in green-retrofit technology, designed to enhance the energy efficiency of refrigerated cabinets with doors. After thorough research, Aerofoil Energy identified why these cabinets often underperform in energy savings and developed Jetseal to tackle a key issue: warm air leakage through door gaps. Retailers implementing Jetseal in their refrigerated cabinets can anticipate a return on investment in under a year. This technology works by harnessing the fridge’s own cold air flow to effectively block warm air from entering through the door gaps, thereby creating a more efficient thermal barrier. Currently undergoing trials with several international grocery chains across the USA and Europe, Jetseal delivers an additional 15-25% energy savings. It is entirely passive and maintenance-free, and replaces door wiper seals for better merchandising and hygiene. It is quick and easy to install, even during store operating hours.

Contracting type: Under development

Technology level: High

Country of origin: United Kingdom

Availability: N/A

Contact: WIPO GREEN Database

Green energy solutions for health care facilities

Health care facilities play a vital role in patient care. While health-care delivery remains a priority, there is growing awareness of the environmental and climate impact of the facilities’ essential functions like heating, cooling, lighting and waste management. These functions determine health outcomes beyond the facility level. At the same time, the always-on requirements of health care facilities heighten their vulnerability to extreme weather events which can disrupt health care services and damage infrastructure. This requires resilient energy infrastructure and back-up systems to safeguard health and protect lives.

Technological developments and trends

The health care sector’s carbon footprint

The health care sector, constituting 10 percent of the world’s gross domestic product, emits a significant amount of GHGs. If the global health care sector were a country, it would be the fifth-largest carbon emitter (

If the global health care sector were a country, it would be the fifth-largest carbon emitter

Emissions from health care facilities themselves represent approximately 30 percent of the global health care sector’s total carbon emissions. The other 70 percent are outside of the scope of this chapter and relate to emissions from the health-care supply chain, including production of pharmaceuticals, hospital equipment, textiles and food

Hospitals have high energy-use intensity

Compared to other commercial building types such as schools and offices, hospitals have nearly three times higher energy-use intensity. More than half of the energy consumption is spent on HVAC (

Geographically, more than half of the sector’s emissions stem from three regions alone: the United States, China and the European Union. While comparisons between countries are often uncertain, it is relevant to note that this regional imbalance remains consistent for per capita emissions; the US health sector produces 57 times more emissions per person than does India. However, there is a strong correlation between the amount of health care spending and the emissions from the sector, marking the important linkage between global sustainability goals such as universal health coverage and climate targets

Global initiatives for green hospitals

Public buildings can be forerunners in the energy transition. We are already aware of the very damaging impacts of climate change on human health across the world, with for instance 37 percent of heat-related deaths being attributed to climate change (

Localized application of technology and innovation play a vital role in the energy transition of a hospital

In the European Union it will soon be mandatory for all but the smallest hospitals to disclose information on their energy and resource use through annual sustainability reports, and global organizations such as Healthcare Without Harm (HHWH) work directly with hospitals to reduce their negative impact on the environment. At COP26, the World Health Organization (WHO) launched the Alliance for Transformative Action on Climate and Health (ATACH) to build climate-resilient and sustainable health systems. While the climate footprint of a hospital is highly influenced by the emission intensity of the energy system in that country

Air quality and humidity a primary concern in hospitals

Maintained and properly designed ventilation systems are critical in hospitals, given the risk of hospital-acquired infections and the direct relationship between certain air pollutants and health problems

Debate persists regarding the optimal humidity levels in hospitals, and their connection to airborne viruses. Several technologies offer efficient solutions for maintaining both high and low humidity levels. For instance, to avoid high humidity levels, a double heat pipe heat exchanger system is recommended over conventional heat exchangers. This not only reduces the risk of fungal growth but also reduces energy consumption

Adaptive and demand-controlled ventilation

Hospital ventilation is often left running continuously, including within unoccupied areas of the hospital overnight

Ventilation can also be further optimized in real time. Demand-controlled ventilation adjusts ventilation rates based on real-time demand and makes use of sensors to monitor factors such as CO2 levels, humidity or occupancy level. Further energy savings could be made by retrieving heat or coolness from exhaust air and transferring it to incoming fresh air, through energy recovery ventilation systems, or by making use of natural ventilation (box 4.4).

Natural ventilation in health care facilities, building on principles such as the stack effect or wind-driven ventilation, offers a connection to the natural environment for patients and saves energy on mechanical ventilation. There is a concern that natural ventilation would be insufficient, or that non-filtered outside air would include contaminants

Heating and cooling consume half of hospitals energy

Improving air conditioning systems is often the most direct and effective way to save energy in health care facilities

The integration between heat pumps and solar energy, such as a solar PV or solar thermal heat pump system, has great potential to save both energy and enable renewable energy integration

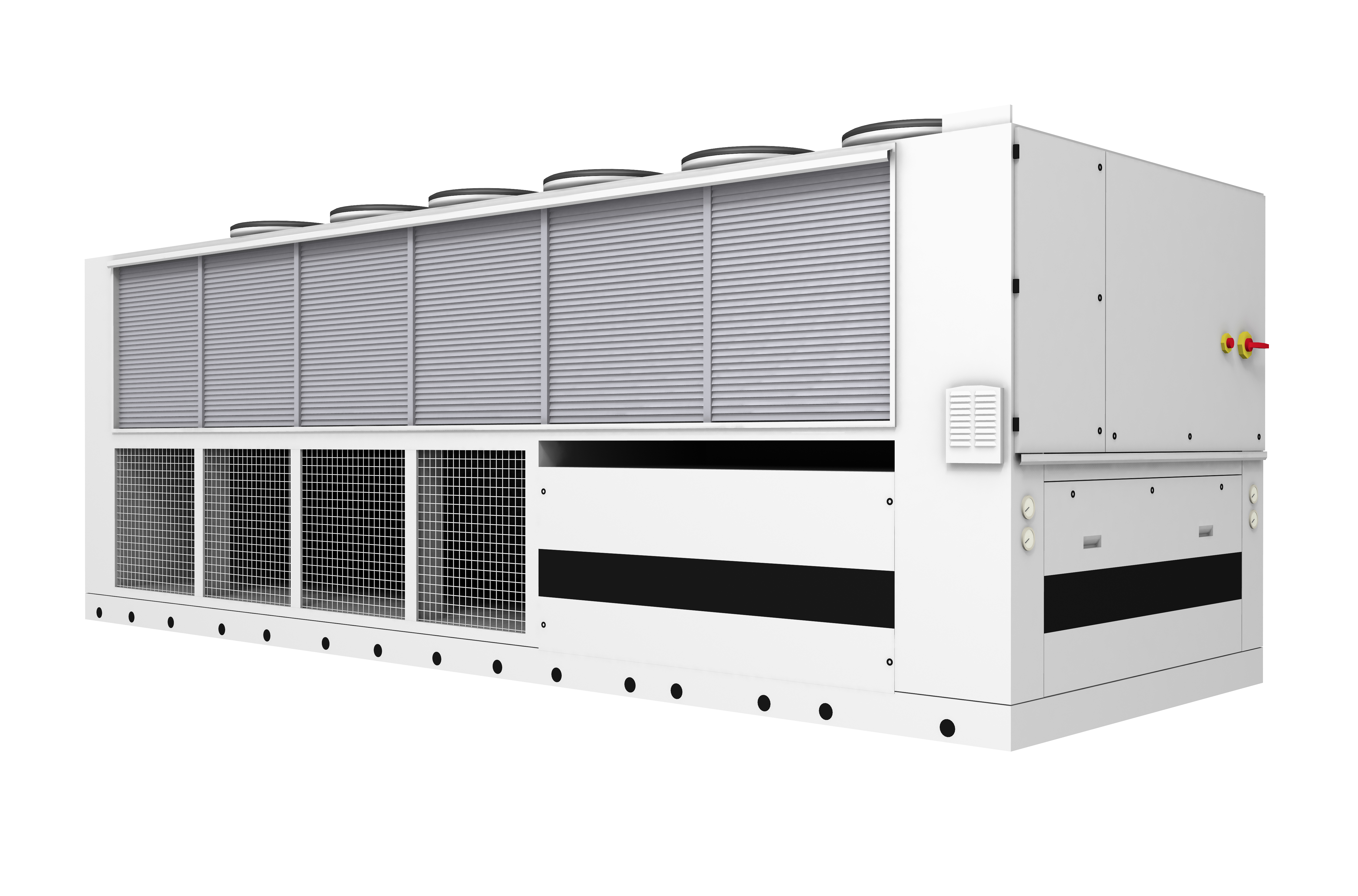

Innovations such as solar absorption chillers, air curtains and variable refrigerant flow (VRF) systems – which circulate only the minimum amount of refrigerant needed during a single heating or cooling period – are also gaining acceptance in the health care market. While VRF systems are helpful in controlling the temperature for individual spaces and are useful for smaller health care facilities, chillers can be more advantageous for larger hospitals

Optimizing medical freezers and laboratory refrigerators

Health care facilities rely on laboratory fridges and medical freezers to store samples, medicines and vaccines. Medical deep freezers, or ultra-low temperature (ULT) freezers that go as low as minus 80 degrees Celsius, are particularly energy-consuming, especially as they age. Their market expanded substantially due to the enormous vaccine storage need brought on by the COVID-19 pandemic

Advances in refrigeration technology for health care facilities means more energy-saving alternatives are available on the market today. Energy-efficient cascade refrigeration systems, better cooling processors, air circulation systems and advanced microprocessor controls for temperature monitoring all contribute to reducing the energy footprint in this area. Furthermore, old freezer models generate more heat to the surrounding room. Replacing them therefore has the bonus of reducing the need for AC, resulting in further energy savings.

Addressing the challenge of 24/7 lighting needs

Health care facilities often require round-the-clock lighting, 365 days a year. Each area of a hospital has its own lighting design needs and requirements with regard to intensity and color. Commonly used fluorescent light tubes are not energy efficient, and also contain traces of mercury. LEDs can reduce energy usage by up to 70 percent

One development is the ability to integrate LEDs with building automation systems. Sensors and IoT integration for adaptive and automated lighting controls are starting to become increasingly relevant for accommodating various lighting needs at different points of the day. Also called luminaire level lighting controls, such data-supported and connected lighting products are gaining in popularity in the health care space

Such adaptive lighting settings may have joint benefits with regard to energy savings, patient care and staff productivity if designed effectively. For instance, rooms may often be more brightly lit than necessary. Studies suggest that very low illuminance (5–60 lx) warm lighting is ideal for night-time conditions in patient rooms and that moderate illuminance (60–300 lx) with high intensity in the red spectrum is more suitable for non-patient areas at night. This so that night shift workers’ circadian rhythms (determining our sleep–wake cycles) are not interrupted, enabling them to remain alert

Possibilities for daylighting, meaning the use of natural light, often depend on the design and positioning of the building and rooms. In addition to reducing electrical lighting needs and save energy, daylighting can have important benefits for patient recovery due to its ability to regulate circadian rhythms. In fact, patients located in rooms with greater exposure to daylight are likely to recover more quickly and with less medication

Technology can help enhance or optimize the impact of daylighting while saving energy. Adaptive glazing technology or window treatment such as low-E films help control glare and excessive solar heat gain, consequently regulating energy use for cooling

Energy-efficient medical equipment

Energy-efficiency is perhaps not considered a priority when designing medical equipment and machinery for patient monitoring, diagnostics and X-rays. Yet, there have been some important technological advances. This is significant, as medical imaging equipment alone accounts for 5 percent of health care facilities’ total energy use. Magnetic resonance imaging (MRI) units, in particular, offer an opportunity for significant energy savings as they are highly energy consuming and up to 40 percent of their energy is consumed when they are not being used during nights and weekends

MRI units are highly energy consuming and up to 40 percent of their energy is consumed when they are not being used during nights and weekends

Innovative MRI units are now on the market using intelligent magnet technology, built-in sleep mode and reduced scan times that contribute to energy conservation. Remaining measures like replacing cathode ray tube monitors with liquid crystal display monitors that use less energy may be small in impact but add up in numbers. Adopting energy-efficient medical equipment is crucial, as it may also be the determining factor for whether health care facilities can rely completely on solar energy or not.

Managing energy consumed by plugged-in devices

A surprising amount of energy can be saved by avoiding electricity “leaks” in machines and appliances and optimizing their use. Plug loads, meaning energy that is consumed by equipment in stand-by mode that is plugged into an outlet, consume a significant portion of energy in hospitals. The expected load can be difficult to predict and manage, sometimes leading to oversized electrical circuits and poorly designed HVAC systems.

New technology areas like learning behavior algorithms and automatic load detection could result in more efficient electricity delivery and use, but further work is needed to scale such solutions on the market

Smart power strips with automatic shutoff functions are commonplace alternatives to at least help avoid phantom leaks from plugged-in devices. However, such measures need to be implemented in a way that does not jeopardize the health and safety of patients, as some devices cannot easily be turned off in a hospital environment due to complicated recalibration settings.

Decentralization enables energy security and renewable energy integration

In order for energy to be decarbonized and used efficiently, it must first be made available. But in fact, close to 1 billion people in low- and lower middle-income countries are served by health care facilities without electricity access or with unreliable electricity. In sub-Saharan Africa, only half of hospitals have access to reliable electricity

Close to 1 billion people in low- and lower middle-income countries are served by health care facilities without electricity access or with unreliable electricity

The main cause of power outages in the electric grid are extreme weather events and natural disasters

Traditionally, on-site energy and back-up systems have been based on fossil fuels. Diesel generators connected to the utility electric grid are less expensive up-front and are the most common form of back-up energy in hospitals. However, where the integration of renewable energy in the grid is slow, several hospitals are moving toward hybrid renewable energy systems to improve the quality and reduce the energy cost of power supply. Advances in solar PVs, batteries and modularity make such systems easier and more affordable for hospitals to adopt

Mini-grids and cogeneration

Among mini-grid options, the trend appears to favor hybrid mini-grids over solar mini-grids

Technological advances have further enabled the combination of fuel cells and CHP systems, which can be particularly relevant for reducing emissions in countries that rely on coal-fired power

Innovation examples

The impact of LED replacements in hospitals

Upgrading from compact fluorescent lamps (CFLs) to LEDs in hospitals presents significant energy-saving opportunities. St. Anthony Hospital (Gig Harbor, Washington, United States) replaced 1,262 CFLs with LED lamps, resulting in a more than 50 percent reduction in energy usage. The LED replacements fit into existing CFL sockets, maintained compatibility with electronic ballasts, and improved lighting quality with consistent color temperature and better rendering of saturated colors. The hospital’s calculated return on investment was 26.3 percent, with an estimated annual energy savings of 131,279 kWh and USD 10,424 in cost savings. With a utility rebate, the project achieved a simple payback period of less than three years

Energy-saving measures at Egyptian hospital reduced energy consumption by 20 percent

The Shefaa Al-Orman Oncology Hospital in Egypt, as a member of the Global Green and Healthy Hospitals (GGHH) initiative, has implemented an ambitious energy efficiency program. In addition to staff awareness raising and training measures, the hospital invested in a number of technological solutions to reduce energy consumption. Changes in equipment included the installation of timers to operate fan coil units more efficiently, scheduling HVAC systems via a building management system, switch to LED lighting, standardization of temperature settings and incorporation of photocell sensors for external lighting. In total, the measures resulted in energy savings amounting to approximately 20 percent, operational cost savings of more than USD 20,000 and a reduction of more than 260 metric tonnes of CO2 emission in a six-month period between 2022 and 2023

Autoclave water and energy recovery at Somerset hospital in Cape Town

Autoclaves are used by hospitals to produce steam from potable water; water which eventually ends up as waste. As the water remains both clean and hot throughout the process, there are significant opportunities for reusing it. An autoclave typically uses about 200 liters of water per cycle, which is eventually discharged as waste at about 40°C. The Somerset Hospital in Cape Town, South Africa installed a heat pump to address this challenge. Clean water is captured through a so-called “Jo-Jo tank” and cooled using a water-to-water heat pump. The cooled water is then pumped back to the autoclave. This installation has resulted in not only water savings but the production of 6,000 liters daily of domestic hot water from waste heat from the autoclaves. Cost savings have amounted to approximately USD 15,750 per year, with a two-year payback period. Roll-out to nearby hospitals is currently underway.

Proven technology solutions

Space heating and cooling: biomass boilers in hospitals

Lasian

Biomass boilers have been adopted by several hospitals as a more low-carbon alternative to conventional fossil fuel-based heating systems. These boilers burn organic materials such as wood pellets, wood chips or other biological waste products to generate heat. Lasian offers a range of domestic and industrial biomass boilers of varying sizes that work with wood pellets, firewood and even olive pits and almond shells, which have a low ash content.

Contracting type: For sale

Technology level: Medium

Country of origin: Spain

Availability: European Union

Contact: WIPO GREEN Database

Space heating and cooling: condensing boilers in hospitals

AERCO

Boilers are required in hospitals for various heating needs such as sterilization, laundry and heating of buildings. As the majority of hospital boilers rely on fossil fuels, alternatives that integrate renewable energy as well as reduce energy consumption are crucial for the energy transition. Condensing boilers are a boiler type that are designed to be more efficient by capturing and reusing heat that would otherwise be lost through a heat exchanger. AERCO’s Benchmark condensing boilers also feature a patented combustion technology that continuously monitors boiling conditions and automatically adjusts combustion processes to maintain ideal oxygen levels and improve system efficiency.

Contracting type: For sale

Technology level: Medium

Country of origin: United States

Availability: Worldwide

Contact: WIPO GREEN Database

Space heating and cooling: automatic blowdown controls

Trilan Energy

Large health care facilities may need industrial steam boilers to cater to their various needs. In a boiler, so-called blowdown can control the build-up of solids in boiler water, protecting the boiler’s surface and improving heat transfer. Often, blowdown is not optimized, which leads to unnecessary energy loss. Trilan Energy provides installation of automatic blowdown controls in industrial steam boilers to continuously monitor boiler water conductivity and ensure that the blowdown rate is appropriate.

Contracting type: For sale

Technology level: Medium

Country of origin: India

Availability: Worldwide

Contact: WIPO GREEN Database

Space heating and cooling: air pre-heater for boiler combustion air

Thermodyne

Thermodyne supplies air pre-heaters which can be used to pre-heat air before it is supplied to the boiler for fuel combustion. This increases combustion temperatures, which leads to more complete and efficient fuel combustion and lower emissions. The heat exchanger heats the incoming combustion air using heat recovered from the boiler’s fuel gases.

Contracting type: For sale

Technology level: Medium

Country of origin: India

Availability: India

Contact: WIPO GREEN Database

Lighting: LED surgical lighting

STERIS

Operating rooms require bright lighting with minimal heat loss for both comfort and practicality, making LED surgical lighting systems and headlamps suitable as they can emit intense white light while emitting low amounts of heat. STERIS’s new lighting system, the HarmonyAIR G-series, uses 70 percent less energy in comparison to previous LED technologies, with a heat-to-light ratio of 3.4.

Contracting type: For sale

Technology level: Medium

Country of origin: United States

Availability: Worldwide

Contact: WIPO GREEN Database

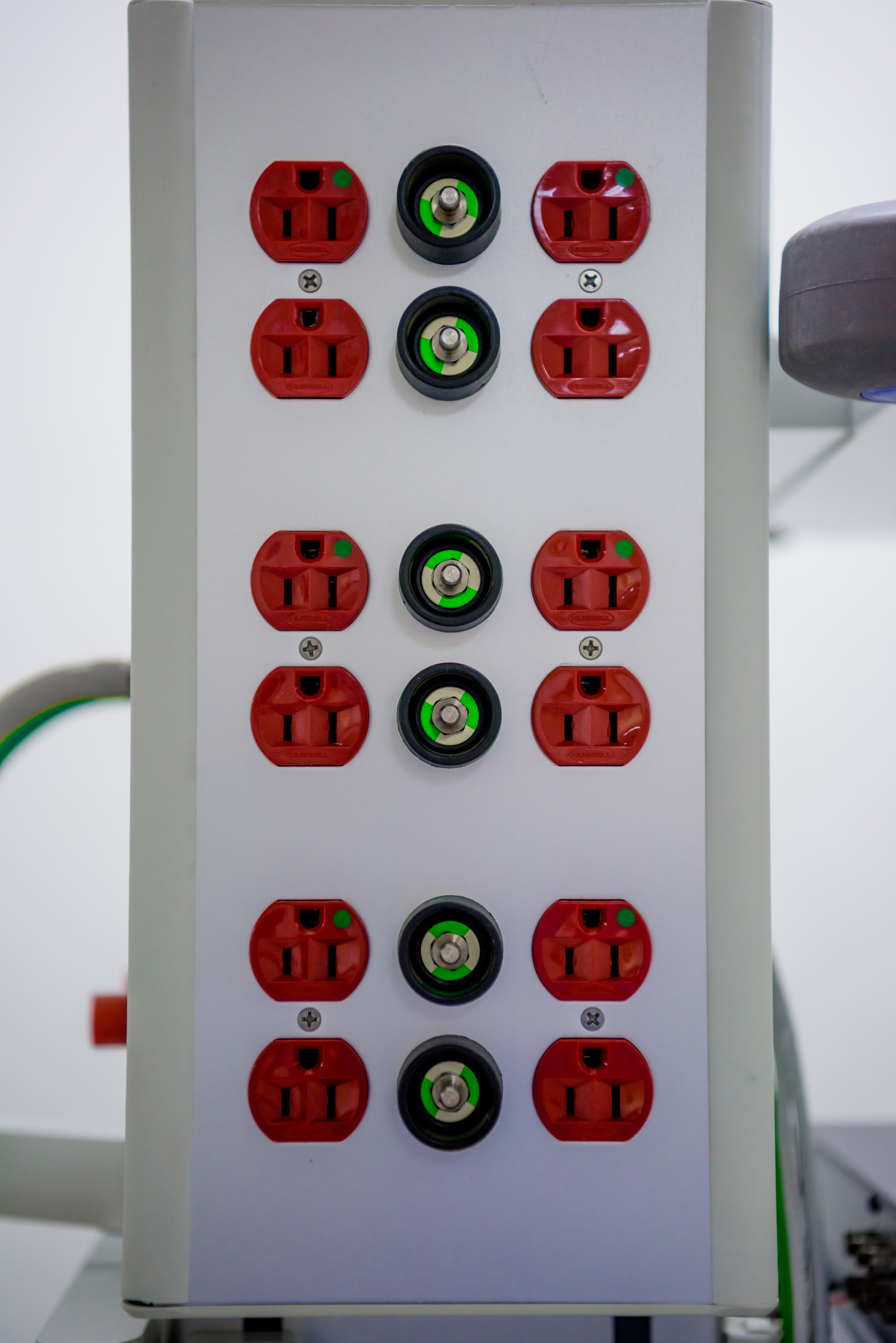

Machines and appliances: medical grade power strips

Leviton

For powering medical equipment in health care facilities, medical grade power strips may be required. Levinton provides such power strips featuring Inform™ Technology – LED indicators which enable real-time monitoring of the load imposed by connected devices, for protection against excess power draw and for compliance with safety regulations. The power strips are also available with surge protection which protects any connected device from damaging voltage spikes.

Contracting type: For sale

Technology level: Medium

Country of origin: United States

Availability: Worldwide

Contact: WIPO GREEN Database

Machines and appliances: energy-efficient medical freezers

Meling Biomedical

The ULT freezers from Meling Biomedical can reach down to –181°C and work with dual compressors to ensure stability in case one would fail. This makes them suitable for medical and lab applications where freezers that can hold stable conditions over a wide range of temperatures are required. These freezers cool with an energy-saving auto-cascade system, using two different refrigerants and dual compressors to reach low temperatures quickly.

Contracting type: For sale

Technology level: Medium

Country of origin: China

Availability: Worldwide

Contact: WIPO GREEN Database

Machines and appliances: energy-efficient autoclaves

Consolidated Sterilizer Systems

Autoclaves utilize steam and variations in pressure to disinfect equipment for health care facilities. The medical autoclaves from Consolidated Sterilizer Systems come with several energy- and water-saving features, including software to schedule startup and shutdown, and automatic temperature regulation between cycles. Energy is saved both during the autoclave’s use phase and because of minimized heat losses to the surrounding environment.

Contracting type: For sale

Technology level: Medium

Country of origin: United States

Availability: Worldwide

Contact: WIPO GREEN Database

Machines and appliances: energy-saving mini cold storage unit

Ningbo Juxin ULT-Low Temperature Technology Co., Ltd.

The Ruibao Platinum Portable ULT Cold Chain Box leverages advanced military-grade Stirling refrigeration technology, functioning as a compact and mobile mini cold storage unit. Designed for versatility, this product is ideal for a range of applications, including ULT storage and transport for laboratories, pharmaceutical cold chain logistics, biological sample preservation and transport and life sciences cold chain operations. Key features of the Ruibao Platinum Cold Chain Box include its broad temperature range compatibility, precise temperature control, high energy efficiency, and a lightweight, compact design.

Contracting type: For sale

Technology level: Medium

Country of origin: China

Availability: Worldwide

Contact: WIPO GREEN Database

Frontier technology solutions

Space heating and cooling: temperature monitoring sensors for hospitals

E-Control Systems

E-control Systems offers temperature monitoring and data management solutions designed specifically for hospitals. The system uses wireless sensors placed in key areas to continuously collect data on temperature, humidity and pressure. The data are analyzed in real time, allowing for immediate alerts if a reading falls outside acceptable ranges. In addition to enabling energy savings by avoiding excess heating and cooling, the solution helps hospitals maintain optimal storage conditions for temperature-sensitive items.

Contracting type: For sale

Technology level: Medium

Country of origin: United States

Availability: United States

Contact: WIPO GREEN Database

Space heating and cooling: solar absorption chiller for hospitals, data centers and shopping malls

Hope Deepblue Air Conditioning Manufacture Corp., Ltd.

In the context of air-conditioning and cooling, solar absorption refers to the use of captured solar heat using solar panels or collectors. The heat is then used to power a cooling cycle which drives a chemical process to create a cooling effect, resulting in chilled water which can be used to cool air or other spaces in buildings. Hope Deepblue Air Conditioning Manufacture Corp., Ltd. supplies a solar absorption chiller particularly suitable for hospitals, data centers and shopping malls.

Contracting type: For sale

Technology level: Medium

Country of origin: China

Availability: Worldwide

Contact: WIPO GREEN Database

Space heating and cooling: antimicrobial cooling towers

Delta Cooling Towers, Inc.

A cooling tower is a large structure used to cool down water by bringing it into contact with air. The cooled fluid is then reused to lower temperatures in for instance HVAC systems. Delta Cooling Towers, Inc. has developed an innovative cooling tower for hospitals that combines cooling with antimicrobial features, as they come with shells made of anti-microbial high-density polyethylene resin to inhibit bacterial growth. The design of the tower also reduces risk of Legionella bacteria colonization.

Contracting type: For sale

Technology level: Medium

Country of origin: United States

Availability: United States

Contact: WIPO GREEN Database

Lighting: intelligent lighting in hospitals

XAL

In health care facilities, lighting is a major energy consumer. Advanced and intelligent lighting systems can enable smarter use of lighting by making sure it is only used when and where it is needed the most. XAL provides sensor-controlled lighting technology for hospitals that can lower energy costs by adjusting brightness based on room occupancy and activity levels. IoT-sensors can be further integrated to allow for analysis of indoor climate in order to connect with and optimize ventilation and air-conditioning use.

Contracting type: For sale

Technology level: Medium

Country of origin: Austria

Availability: Worldwide

Contact: WIPO GREEN Database

Machines and appliances: energy-efficient MRI machines

GE Healthcare Technologies, Inc.

MRI scanners require helium, a non-renewable resource, to cool the magnet to suitable working temperatures. GE Healthcare Technologies has developed the SIGNA™ 3T MRI scanner, which, compared to its predecessors, is stated to require 67 percent less helium and features a magnet that is 1.4 times more efficient. This increased efficiency translates into potential energy savings due to the reduced time required for scanning. Furthermore, the company offers retrofitting options for their scanners, enabling material savings through initiatives such as the SIGNA™ Continuum™ program.

Contracting type: For sale

Technology level: High

Country of origin: United States

Availability: Worldwide

Contact: WIPO GREEN Database

Energy supply and storage: internet portal for monitoring of renewable energy integration

SMA Solar Technology

Integrating solar and wind energy systems in hospitals is possible, but relies on a number of enabling technologies. For instance, the energy system may need to be monitored to understand its performance. The sunny WebBox is such a product that enables energy system monitoring, remote diagnostics, data storage and visualization. A large display unit with data of interest can be installed in the hospital foyer for the general public interested in knowing the amount of energy generated and carbon emissions avoided to date. While not reserved for hospitals, the Khayelitsha hospital in South Africa is an example of a hospital which has installed the system.

Contracting type: For sale

Technology level: Medium

Country of origin: Germany

Availability: Worldwide

Contact: WIPO GREEN Database

Horizon technology solutions

Energy supply and storage: hydrogen back-up for hospitals

EODev

The GEH2® hydrogen genset, developed by EODev, provides a solution for continuous or back-up decarbonized electricity production. It delivers 100 kVa of clean energy with zero emissions of CO2, NOx or fine particles, making it ideal for urban settings, hospitals and construction sites. The genset operates with low noise, no odors and immediate startup, and the thermal energy produced can be used for heating. While hydrogen storage is managed separately by the customer, distributors and partners assists in defining appropriate storage and supply solutions according to regulations.

Contracting type: For sale

Technology level: High

Country of origin: France

Availability: Worldwide

Contact: WIPO GREEN Database

Energy supply and storage: solar-powered sterilization of medical equipment

Massachusetts Institute of Technology (MIT) and Indian Institute of Technology (IIT) Bombay

The use of solar thermal energy for autoclaves is not new and has been used since the 1970s

Contracting type: Under development

Technology level: High

Country of origin: United States and India

Availability: N/A

Contact: WIPO GREEN Database

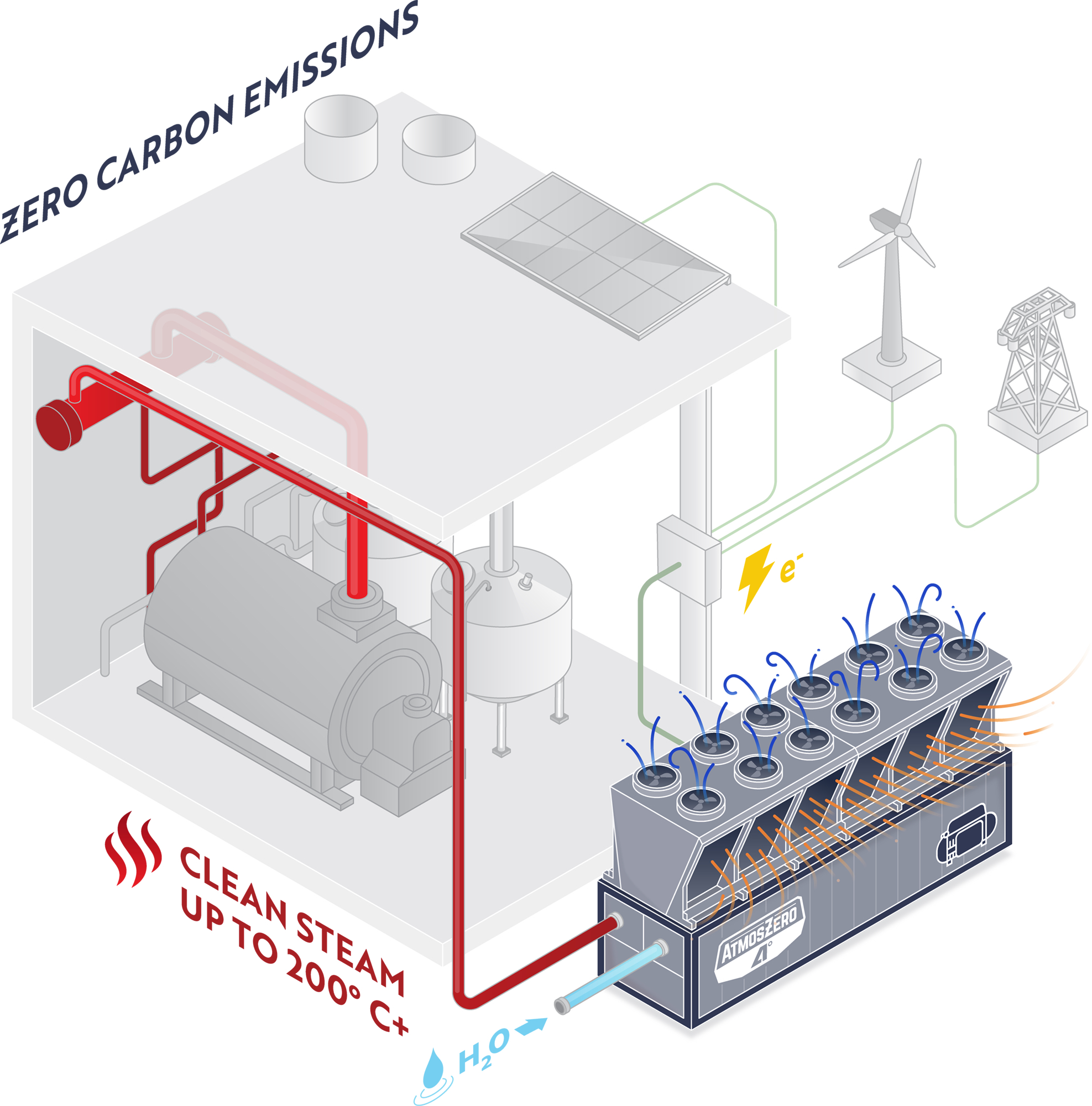

Space heating and cooling: air-sourced electric boiler for decarbonized steam

AtmosZero

The Boiler 2.0 is a new alternative to combustion and electric resistive boilers with zero on-site emissions. It is a modular and drop-in heat pump solution, utilizing the heat in ambient air and electricity to generate up to 200°C steamwith a cascaded vapor compression cycle. The process has an efficiency of more than 100%, meaning that the output in heat energy is greater than the input of electrical energy. This contrasts with combustion boilers, which operate at lower efficiencies and emit pollutants that reduce local air quality. The Boiler 2.0 can be used in various applications and industries, with examples such as pasteurization in food processing, distillation in chemicals, or sterilization and heating in healthcare facilities. A 650-kW thermal installation will be tested at an American brewery in Q1 2025.

Contracting type: Under development

Technology level: High

Country of origin: United States

Availability: N/A

Contact: WIPO GREEN Database

Energy smart data centers

Data centers, the backbone of our digital lives, are notorious for their substantial energy consumption and environmental impact. This chapter explores innovative climate solutions aimed at managing data centers’ power consumption, cooling and operations to mitigate their climate change impact.

Technological developments and trends

Data centers – climate friend or foe?

Whenever we scroll social media, send an email or use ChatGPT, servers in a data center are working behind the scenes to store and process the data. From small corners in an office building to hyperscale data centers, thousands of racks of equipment are in constant need of electricity and cooling. As artificial intelligence (AI), the gaming industry, the metaverse and other digital sectors expand, the demand for data is increasing. And as more and more servers must be cooled, the substantial water and energy consumption of data centers has become a serious concern (see box 4.5).

As more and more servers must be cooled, the substantial water and energy consumption of data centers has become a serious concern

In China, regulators have mandated the adoption of innovative energy-saving technologies and use of renewable energy sources for data centers

While AI is an important driver behind data centers‘ growing energy demand, it also offers promising new thermal cooling solutions for data centers that are ready to integrate AI into their own operations

At the same time, the applicability of AI is broad, meaning it can contribute to driving up emissions in several ways. For instance, by enabling more fossil fuel exploration, or by simplifying the design of targeted digital ads toward consumers that ultimately increase consumption. The combined effect of such activities is not yet well researched, and as such the net climate impact of AI and data usage on climate change is largely uncertain

What we do know is that data and AI use is here to stay. Since 2010, the global number of internet users has more than doubled

Location of data centers impacts energy consumption

The energy demand from data centers is highly uneven across regions and countries. In Ireland, data centers are expected to consume nearly a third of the nation’s electricity by 2028 (EirGrid). However, Ireland is also considered Europe’s data center capital, hosting more than 80 data centers with another 50 underway. Globally, there are currently more than 8,000 data centers, with about 33 percent of these located in the United States, 16 percent in Europe and nearly 10 percent in China

The number of data centers is relatively small in Africa. But grid and internet expansion is expected to cause the regional data center market to double in the next two years alone, presenting an opportunity to implement climate-smart and resilient solutions from the start

The geographical location of data centers plays an important role for their energy consumption and climate impact, with the local energy mix being a key determinant. Countries with a cool climate and secure supply of green electricity such as Canada and the Nordic countries are attracting cloud computing centers and hyperscale facilities, with major companies such as Google, Meta and Amazon having established facilities there in recent years

Moreover, the local climate plays an important role. Maintaining hardware and servers within recommended temperature and humidity guidelines is essential to avoid overheating and damage. Data centers in warm countries require more energy for cooling, which is why even locations such as the Arctic have become the subject of interest. The location also has an impact on the type of cooling technology used at a data center, with certain cooling techniques demanding specific geographical conditions such as cold outside temperatures or access to a lake, river or sea (see sections on cooling below).

A common assessment is that data centers and transmission networks account for 2 to 3 percent of global electricity consumption

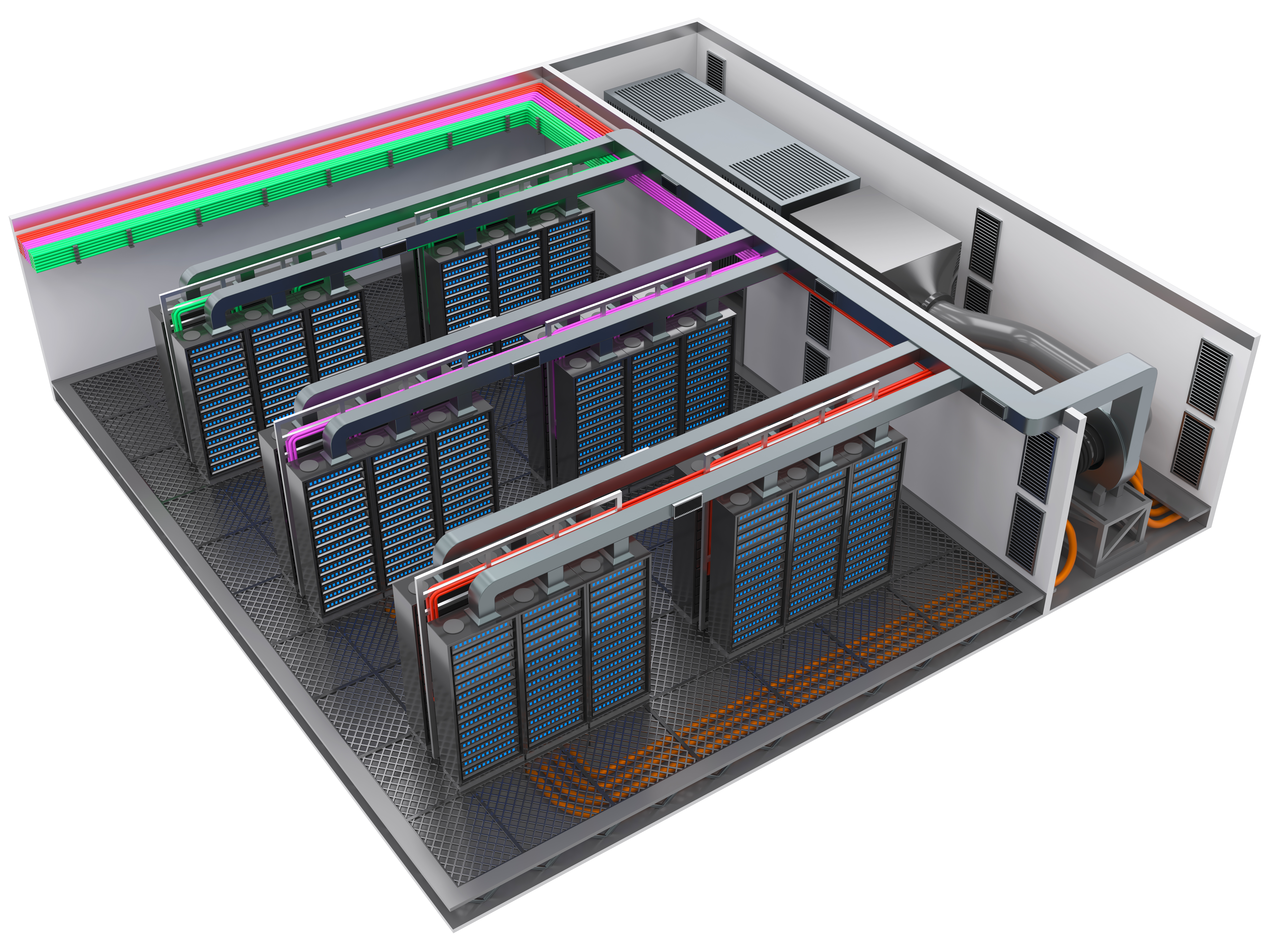

Electricity demand in data centers is mainly driven by the servers and cooling systems, which each account for 40 percent of electricity use. The remaining 20 percent comes from other associated equipment such as storage devices and communication equipment

Water use is another challenge. An estimated 700,000 liters of water were potentially used to cool the machines that trained ChatGPT-3 at Microsoft’s data facilities, and total global demand for AI may be accountable for up to 6.6 billion cubic meters of water withdrawal in 2027. However, resource consumption numbers from data centers are often uncertain, owing to the secrecy of private companies that operate them

Finally, it is relevant to note that the location of data centers in turn can have an impact on grid efficiency and renewable energy deployment. As major energy consumers, data centers risk causing grid congestion or impacting the availability of connection points for other users such as renewable energy parks. However, smart planning can mitigate this challenge. Strong collaboration with electricity transmission system operators can enhance grid optimization and stability, by for instance co-locating data centers in nodes with high renewable energy production, allowing the centers to draw from these installations instead.

Energy-efficient hardware and software

Energy-efficient hardware and software can help data centers significantly reduce their power demand, as IT equipment such as servers, storage devices and networking equipment accounts for a significant amount of the energy consumption

In addition to the hardware itself, IT accessories that can enable higher efficiencies and reduce energy loss include couplings, insulation and high-efficiency cable connectors designed to ensure a smooth flow of electricity and secure connections between cables.

Data centers risk causing grid congestion or impacting the availability of connection points for other users such as renewable energy parks

Identifying energy-efficient software is more challenging, but forecasting and measurement tools for such purposes are being developed, and approximations can be drawn based on the power draw from hardware to achieve results. Writing more lean software codes and avoiding overly complicated codes are examples of energy-saving practices. Once methods for measuring power consumption of software are in place, programming language can be adapted to develop more energy-efficient software

Furthermore, significant energy could be saved through advanced power semiconductors and other innovations that help enable high data processing performance. New materials such as gallium nitride (GaN) are being explored in semiconductors to increase efficiency and power density in data centers

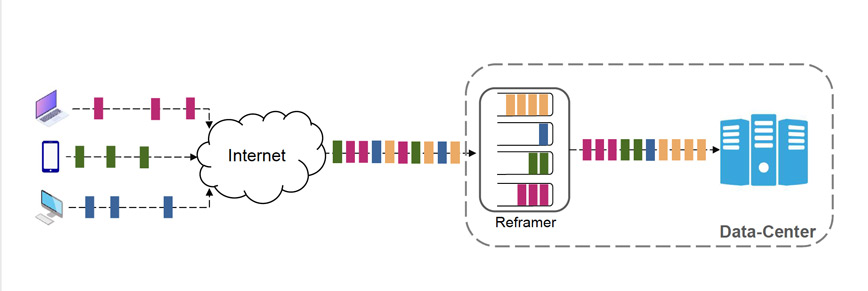

Virtualization and load balancing enhances both energy efficiency and climate resilience

A data center runs on multiple hardware and server configurations. Virtualization is a technology that allows data centers to create virtual versions of these physical resources. These virtual versions (or “virtual machines”) can then run on a single machine, optimizing their use and enhancing efficiency. A so-called virtual machine monitor (VMM) then acts as the operating system, which can also help manage power use and facilitate an efficient allocation of hardware resources.

By going further and allowing each virtual machine to manage its own energy management strategy, and by using a system for managing computer resources (or a virtualization infrastructure provider) , significant power can be saved. Such a system can save up to 27 percent energy and run programs that require a lot of processing power up to 32 percent faster compared to standard settings in a VMM

Another practice that can enhance efficiency is load balancing, involving optimization of workload between data centers. This balancing of load on servers helps improve the performance of data centers and minimize energy use and processing time in cloud systems

In the context of climate adaptation, both virtualization and load balancing can contribute to enhancing data centers’ resilience. In addition to the remote management opportunities, virtualization simplifies the process of moving and replicating virtual machines, enabling more efficient recovery processes after disasters and extreme weather events. Load balancing, on the other hand, allows data centers to distribute workloads across multiple servers and locations. In the event of extreme weather affecting one location, workloads can be dynamically shifted to unaffected data centers.

Greening back-up generators, or avoiding them altogether

Many data centers are dependent on back-up generators, often run on fossil fuels such as diesel, to guarantee consistent power supply. Fossil-free back-up alternatives and battery-based systems are still limited but are becoming more common, with innovative sources such as hydrogen being explored. The advantage of a battery-based system is that compared to diesel generators they can avoid startup times and don’t need to sit idle when there are no power outages, but could potentially be used as assets to strengthen the electric grid by banking renewable power and balancing variability

Hydrogen-powered fuel cell generators are currently being developed by energy companies in collaboration with data centers. To date, a number of demonstration units have been piloted to test the technology. However, this often uses hydrogen made from natural gas and not green renewable hydrogen

From air cooling to liquid cooling

Today, the sheer size of data centers means standard air conditioning systems are no longer sufficient. Instead, conventional data centers frequently use computer room air handlers or computer room air conditioning units to cool down hardware. Implementing control systems that take factors such as cooling load and air temperature into account can help optimize the cooling system in real time. Many of these units now have the option to connect their control systems and run together to work more efficiently.

In addition to air conditioners, more specialized cooling technologies are needed for the hottest most power-hungry components of data centers. A typical shift in the sector can be seen in terms of moving from air cooling to liquid cooling which generally provides more efficient cooling

Immersion liquid cooling: this cooling technology has gained in popularity. It cools by submerging equipment directly in coolant, which makes heat transfer more efficient. The coolant has high thermal conductivity and stable temperatures, reducing energy use, noise and the need for fans. This technology is ideal for large data centers, supercomputing and research institutions needing high cooling efficiency and energy savings. It’s particularly useful in cold, high-altitude areas with limited space and in data centers near offices and residential areas due to its low noise

Cold-plate liquid cooling: direct-to-chip cooling refers to liquid coolant being delivered directly via tubes to cold plates directly on chip surfaces. This method provides more targeted cooling for high-performance components, resulting in better thermal management. Pipes connect liquid to cooling plates on the computer’s high-power parts, while other parts are still cooled by air. This method is more efficient, quieter and cheaper than using air alone

Spray cooling: this also involves direct contact with liquid, similar to immersion cooling, but here the dielectric liquid is sprayed directly onto the hottest parts of the servers. The servers are kept at an inclination to allow the liquid to then flow down and be collected in a small tank at the bottom, filtrated and fed through a heat exchanger. Being a more recent innovation, spray cooling is not as common as immersion and cold-plate liquid cooling

Free cooling technology makes use of the natural elements

The need for enhanced efficiency has led to the development of adiabatic and free cooling technology for data centers. By making use of naturally available air and water, free cooling can replace part or all of data centers mechanical cooling needs. This necessitates locating the data center in a cold climate or close to a body of water that can act as a cooling source

Adiabatic cooling – or evaporative cooling – uses the process of water evaporation to cool the air, where warm air is passed over water-soaked pads or misted with water, reducing the air temperature before it is circulated through the data center. This method is particularly energy-efficient and effective in regions with low humidity. However, while this may save on energy it is very water-consuming. As an attempt to overcome this challenge, pilot demonstrations in recent years have even tested underwater data centers that use sea water as a natural cooling source

Geothermal cooling has been around for a while but its use in data centers is limited due to geographic constraints. These systems cool data centers by using the ground as a heat sink, operating a closed-loop piping system filled with water or coolant which transfers heat to underground wells.

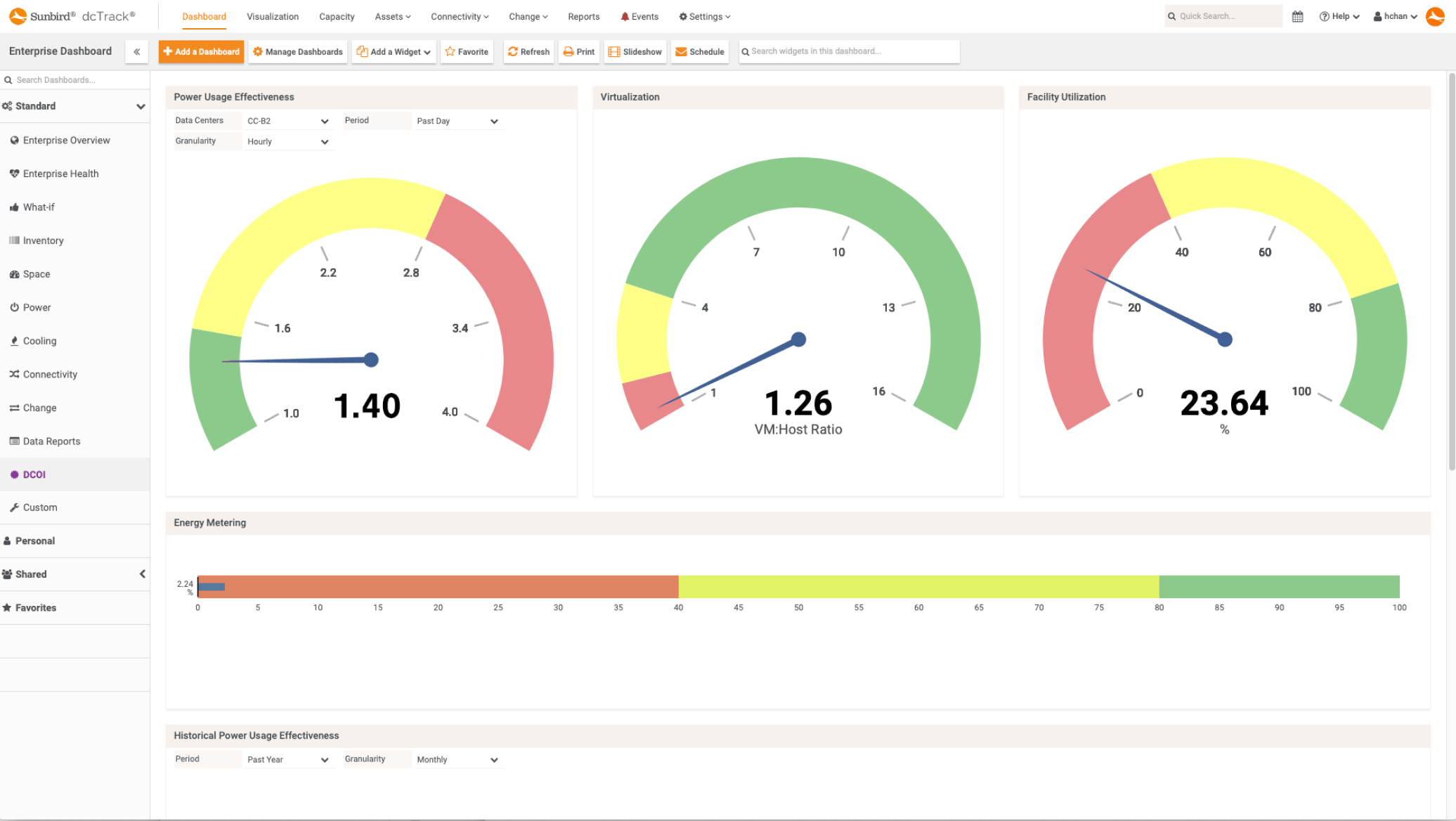

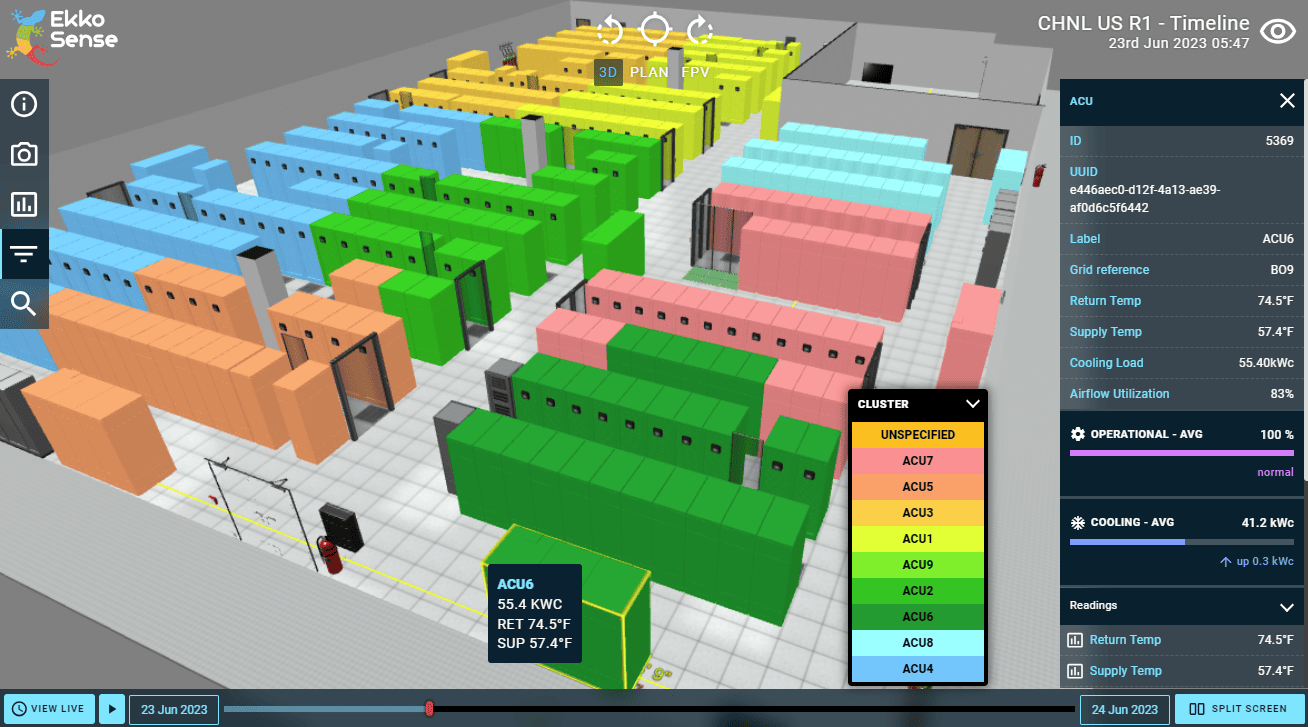

Managing airflow